How is Iron Refined into Steel?

2024-12-09 14:14:53 hits:0

Steel is an indispensable material in modern industry and daily life. From constructing bridges and manufacturing cars to crafting household tools, steel plays a critical role. But how is iron transformed into steel? This article explores the fascinating process of refining iron into steel.

The Difference Between Iron and Steel

Before discussing the process of making steel, it’s essential to understand the differences between iron and steel:

- Iron: Refers to pure iron or iron alloys with a low carbon content. It is flexible but lacks strength.

- Steel: An iron-carbon alloy with a carbon content of 0.02% to 2%. Its properties can be optimized by adjusting the carbon content and adding other elements (e.g., manganese, nickel, chromium). Compared to iron, steel offers higher strength and toughness.

Key Steps in Refining Iron into Steel

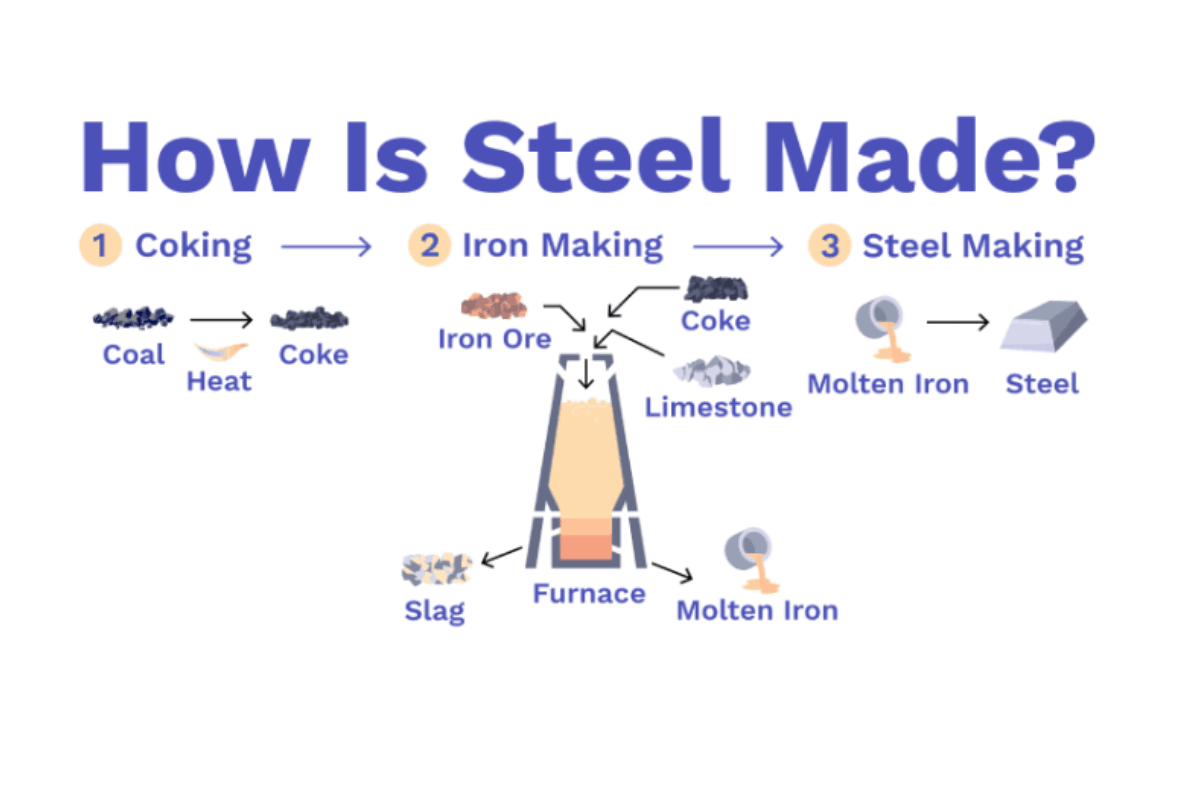

1.Preparing Raw Materials

The main materials used for steel production are pig iron, scrap steel, and alloying elements:- Pig Iron: Produced by smelting iron ore in a blast furnace, it has a high carbon content (about 3%-4%) and is brittle.

- Scrap Steel: A recycled resource in steel production, reducing material costs.

Alloying Elements: Added to enhance specific properties, such as nickel for corrosion resistance or chromium for hardness.

2.Steelmaking Processes

The core of steelmaking is reducing the carbon content of iron and removing impurities (e.g., sulfur, phosphorus). Modern steelmaking methods include the following:Basic Oxygen Furnace (BOF) Steelmaking

The BOF is the most widely used method for steel production globally.

- Hot molten pig iron and scrap steel are charged into the furnace.

- Oxygen is blown into the furnace to oxidize carbon and impurities, which are released as gas or slag.

- The carbon content and impurities are controlled to produce steel with the desired composition.

Electric Arc Furnace (EAF) Steelmaking

EAF is particularly suitable for producing high-quality steel using scrap metal.- Scrap steel is melted using the high temperature of an electric arc, with alloying elements added as needed.

- The process allows precise control of temperature and composition, ideal for producing specialty steels.

Open Hearth Furnace Steelmaking (Traditional Method)

This older method uses heat from burning fuels to refine iron into steel on a refractory hearth. Though less efficient, it played a pivotal role in historical steel production.3.Refining Molten Steel

After steelmaking, molten steel undergoes further refining to enhance quality:- Desulfurization and Deoxidation: Specific agents are added to remove residual sulfur and oxygen.

- Alloying: Elements are added to tailor the composition for specific applications.

- Vacuum Treatment: Reduces gas impurities like hydrogen and nitrogen to prevent porosity or cracking in the steel.

4.Casting and Forming

Refined steel is cast into molds to cool and solidify into billets, which are then processed further:- Primary Rolling: Converts billets into steel plates, pipes, or bars.

- Advanced Processing: Includes cutting, welding, or surface finishing to meet design requirements.

Modern Advances in Steel Production

As technology advances, steelmaking processes have become more efficient and environmentally friendly:- Energy-Saving Technologies: Modern furnaces and BOF steelmaking significantly reduce energy consumption and emissions.

- High-Strength Steel: Lightweight yet strong steels, developed using alloy design and heat treatment, are used in automotive and aerospace industries.

- Green Steelmaking: Hydrogen is being explored as a replacement for coke as a reducing agent, reducing carbon dioxide emissions and supporting sustainable development.

Applications of Steel

Steel's exceptional properties make it indispensable across various industries:- Construction and Infrastructure: Used in bridges, skyscrapers, and railway systems for its load-bearing capacity.

- Manufacturing: From automobiles to household appliances, steel’s durability and versatility make it an ideal material.

- Energy Sector: High-strength steel supports wind turbines, oil pipelines, and nuclear reactors.

- Household Tools: Everyday products like cookware, knives, and furniture often rely on steel.

The process of refining iron into steel is complex and precise, combining chemistry, physics, and engineering. From ancient smelting furnaces to modern intelligent steel mills, advancements in steelmaking have driven industrial progress. Steel production not only meets today’s societal needs but also lays the foundation for future development. If you’re curious about the science and technology behind steelmaking, it’s a fascinating field worth exploring!

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh