Key Insights into Construction Machinery Castings: Products, Materials, and Standards

2024-12-09 13:40:30 hits:0

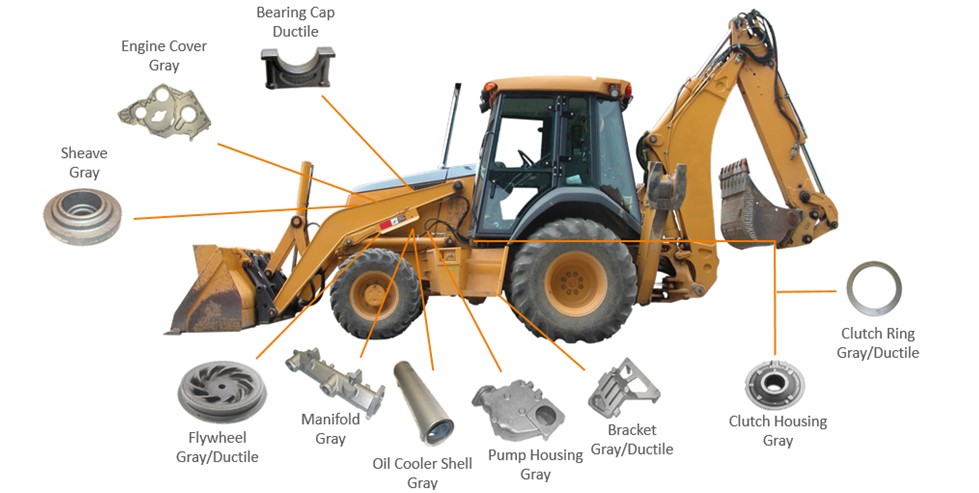

Construction Machinery Castings refer to metal castings used in construction machinery equipment. These castings are typically required to withstand high strength, high wear, and complex working environments, demanding high-quality and performance standards. Below is an introduction to the main products, raw material requirements for pig iron, and related standards:

Main Products

Excavator Components

- Buckets

- Bucket Teeth

- Bucket Edge Plates

- Bucket Connecting Parts

Loader Components

- Buckets

- Rocker Arms

- Articulated Joints

Bulldozer Components

- Track Links

- Drive Wheels

- Support Rollers

- Carrier Rollers

Other Construction Machinery Parts

- Crane Hooks

- Gearbox Housings

- Brake Discs and Brake Drums

Requirements for Pig Iron as Raw Material

Chemical Composition

- Carbon Content: Generally 2.5%–3.6%, ensuring good casting performance.

- Silicon Content: Typically 1.0%–2.0%, improving fluidity and casting toughness.

- Sulfur and Phosphorus Content: Preferably below 0.08% and 0.05%, respectively, to reduce brittleness in castings.

Mechanical Properties

- Pig iron must have good strength and ductility to ensure castings can withstand complex working environments.

Impurity Control

- Should contain low levels of non-metallic inclusions (e.g., oxides, silicates).

Wear Resistance

- For components requiring high wear resistance (e.g., bucket teeth), appropriate amounts of alloying elements such as chromium, manganese, or vanadium can be added.

Product Standards

International Standards

- ASTM A532 (High Chromium Cast Iron): Applicable to wear-resistant castings.

- ASTM A48 (Gray Cast Iron): For general-purpose mechanical castings.

- ISO 1083 (Ductile Cast Iron): Emphasizes toughness and impact resistance.

Chinese Standards

- GB/T 9439-2010 (Gray Iron Castings)

- GB/T 1348-2009 (Ductile Iron Castings)

- GB/T 11352-2020 (Carbon Steel Castings for General Engineering)

Industry Standards

- Customized specifications may exist depending on specific machinery industries (e.g., construction machinery, building equipment).

Additional Considerations

Quality Control

- Strictly monitor the melting process's temperature and chemical composition.

- Conduct non-destructive testing (e.g., ultrasonic, X-ray) to ensure no internal defects in the castings.

Heat Treatment

- Apply heat treatments such as normalizing, quenching, or tempering to certain castings (e.g., high-wear components) to enhance strength and toughness.

Surface Coating

- Casting surfaces are typically coated with anti-rust paint to enhance corrosion resistance.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh