Characteristics of Stamping Forming

2024-12-05 15:40:36 hits:0

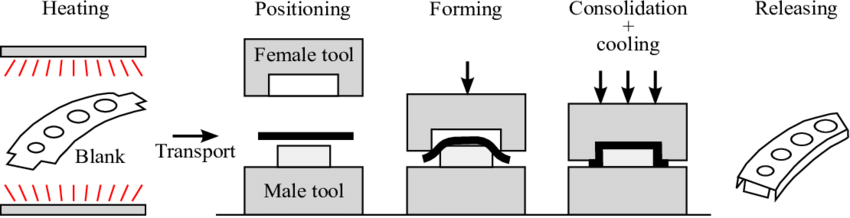

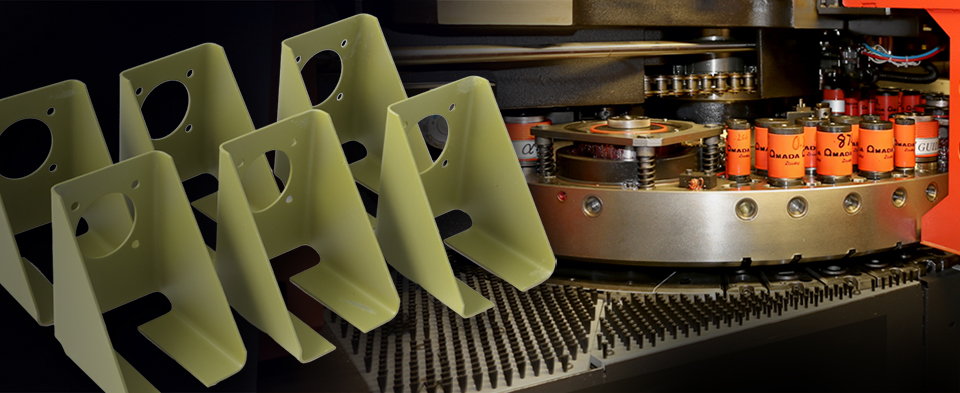

Stamping forming is a widely used manufacturing process in the field of metalworking. It uses molds and stamping equipment to apply pressure to sheet metal, causing plastic deformation to achieve the desired shape. Its unique features make it widely adopted in industries such as automotive, aerospace, and household appliances. This article analyzes the key characteristics and advantages of stamping forming from the perspective of the foundry industry.

Key Characteristics of Stamping Forming

1.High Efficiency and Low Cost

Stamping is a highly efficient production process, especially suitable for mass production. With one press, it can produce complex and precisely sized parts, reducing subsequent processing steps and lowering production costs.2.High Material Utilization

In stamping, raw materials are primarily used in sheet form, offering a higher utilization rate compared to other processes like machining or casting. This reduces material waste and aligns with modern green manufacturing principles.3.Stable Product Quality

The precision of the molds ensures that stamped parts exhibit consistent shapes and dimensions. By optimizing mold design, tolerances and surface quality can be effectively controlled.4.Excellent Mechanical Properties

During the stamping process, the metal material often undergoes work hardening, which enhances the strength and stiffness of the parts, making them more durable in practical applications.5.Wide Applicability

Stamping forming is suitable for various metal materials, including steel, aluminum, copper, and their alloys. It can produce simple flat parts as well as complex curved structures, meeting diverse industry demands.6.Adaptability to Automation and Smart Production

Stamping can integrate with automated equipment and intelligent control systems, enabling the deployment of unmanned production lines. This improves production efficiency and reduces labor costs.

Comparison of Stamping Forming and Casting Processes

1.Different Forming Methods

- Stamping forming is a cold working process that relies on external force to cause plastic deformation in sheet metal.

- Casting involves solidifying molten metal, which is suitable for manufacturing large and complex parts.

2.Materials and Applications

- Stamping is more suitable for thin-walled parts, small structural components, and mass production.

- Casting is often used for thick-walled parts, large components, or complex cavity structures.

3.Economic Considerations and Batch Sizes

- Stamping forming is cost-effective in mass production but has high initial mold development costs.

- Casting is ideal for small-batch or trial production, with relatively lower mold costs.

4.Part Performance

- Stamped parts gain strength and surface quality through work hardening.

- Castings allow greater optimization of properties through composition and heat treatment control.

Limitations of Stamping Forming

1.High Material Performance Requirements

Stamping requires materials with good plasticity and processability, limiting the use of some high-hardness metals.2.Expensive Mold Costs

The design and manufacturing cycle for stamping molds can be lengthy, with high upfront investment, making it unsuitable for small-batch or experimental production.3.Complexity Constraints

Stamping is primarily suitable for thin-walled and simple curved parts. For multi-thickness or complex internal cavity parts, casting offers better flexibility.

With its efficiency, precision, and cost-effectiveness, stamping forming plays a vital role in manufacturing. However, when compared to casting, each process has its strengths and weaknesses. Foundry industry professionals must choose the most suitable forming method based on part functionality, production volume, and economic factors to achieve the optimal balance between performance and cost.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh