How to Choose the Right Cast Iron Casting Process?

2024-11-21 09:48:31 hits:0

Cast iron is a critical material in industrial manufacturing, valued for its excellent mechanical properties, heat resistance, and corrosion resistance. However, selecting the appropriate casting process based on specific application needs and production conditions is essential. A well-chosen casting process can improve product quality, reduce production costs, and enhance manufacturing efficiency. In this article, I will discuss the common processes of cast iron casting and their applicable scenarios to help readers understand how to choose the appropriate casting method.

1.Common Cast Iron Casting Processes and Their Features

The main casting processes for cast iron include sand casting, lost foam casting, precision casting, and pressure casting. Below are the characteristics and applications of these methods:

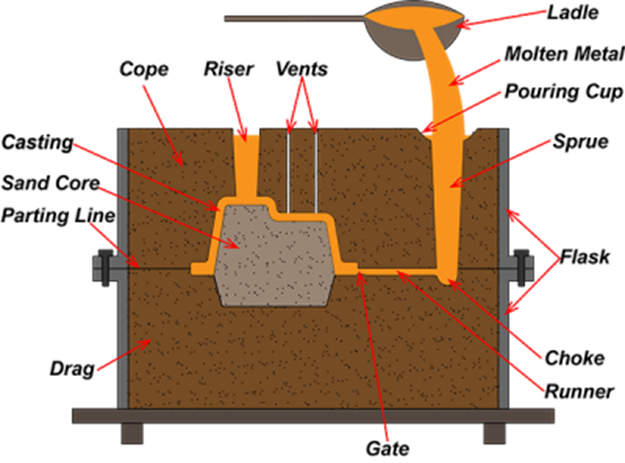

1.1 sand casting

Sand casting is one of the oldest and most widely used casting methods. It is cost-effective and versatile, suitable for producing a wide range of cast iron products, from small components to large structures

- Advantages:

Ideal for complex structures and large workpieces, with high material utilization. - Disadvantages: Poor surface quality, low dimensional accuracy, and significant post-processing requirements.

- Applications:Examples include pipe fittings, machine tool bases, and pump housings.

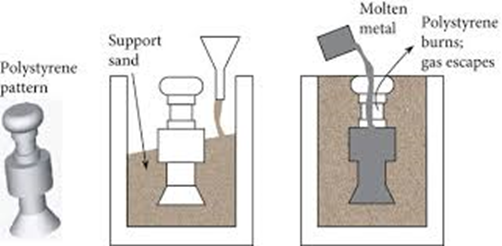

1.2 Lost Foam Casting

Lost foam casting uses foam models instead of traditional sand molds. The model vaporizes when molten metal is poured in. This process offers high flexibility in production.

- Advantages: No need for mold parting, suitable for complex shapes, and reduces post-processing.

- Disadvantages: High precision requirements for the model and higher mold costs.

- Applications: Examples include automotive parts, valve bodies, and pump bodies.

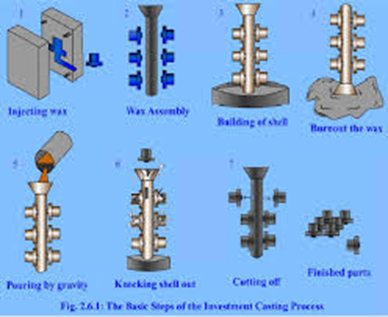

1.3 Precision Casting

Precision casting involves creating high-accuracy castings using wax or ceramic molds. It is often used for products requiring excellent surface quality and dimensional precision.

- Advantages: High accuracy and excellent surface quality, with minimal machining required

- Disadvantages: Higher cost and longer production cycles.

- Applications: Examples include aerospace components and high-end machinery parts

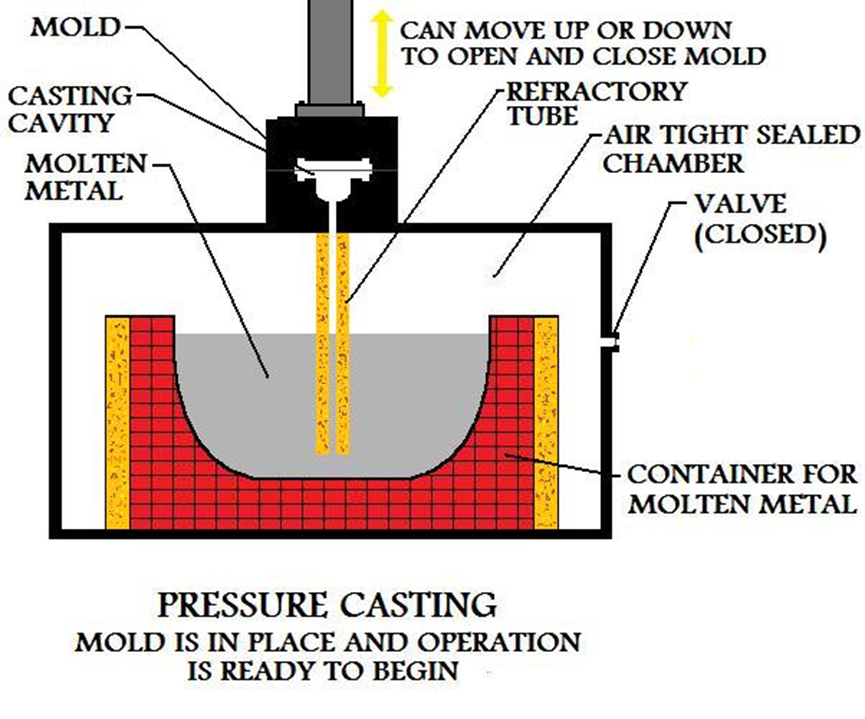

1.4 Pressure Casting

Pressure casting forces molten metal into a mold under high pressure for rapid shaping. This method is suitable for mass-producing small, lightweight components.

- Advantages: High production efficiency, ideal for large-scale manufacturing, and

uniform product quality.

- Disadvantages: High equipment investment and not suitable for large castings.

- Applications: · Examples include automotive components and electronic device housings.

The most

common casting processes are the above ones. So how should we choose according

to our needs? Let's continue reading

The most

common casting processes are the above ones. So how should we choose according

to our needs? Let's continue reading

2. How to Choose a Cast Iron Casting Process

When selecting a casting process, multiple factors should be considered, including product design requirements, production costs, batch size, and specific application environments.

2.1 Based on Product Design Requirements

Complexity: For complex-shaped parts, consider lost foam casting or sand casting.

Dimensional Precision: For components with high precision and excellent surface quality requirements, precision casting is the best choice.

Wall Thickness: For thin-walled castings,

pressure casting is highly effective.

2.2 Based on Material Performance Requirements

Different types of cast iron (e.g., gray

iron, ductile iron, white iron) exhibit varying casting properties:

Gray iron is suitable for sand casting due

to its good fluidity and stable solidification.

Ductile iron works well with pressure or

precision casting, as it retains superior mechanical properties after forming.

2.3 Based on Production Cost and Scale

Small Batch Production: Sand casting is the

first choice due to its low mold cost and high flexibility.

Mass Production: Pressure casting is ideal

for its high efficiency, making it suitable for large-scale manufacturing.

2.4 Based on Industry Requirements

Automotive Industry: Pressure casting or

lost foam casting is often used to meet high strength and precision demands.

Construction Machinery: Sand casting is

commonly used due to its cost-effectiveness and versatility.

High-End Manufacturing: Precision casting

is preferred for aerospace or medical equipment components.

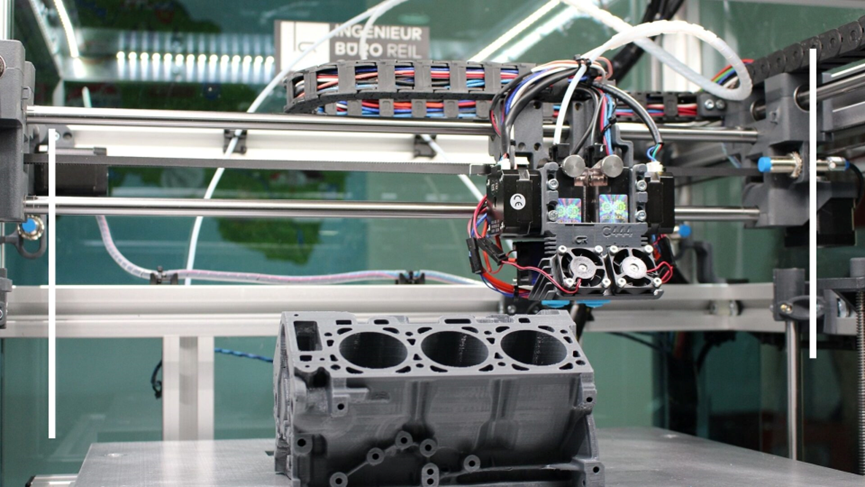

3. Future Developments in Cast Iron Casting Processes

With technological advancements, casting

processes are continually improving. For instance, the introduction of 3D

printing has made mold production more efficient and precise. Additionally,

environmental concerns are driving the development of greener processes, such

as techniques to reduce waste sand and gas emissions. These innovations make

casting process selection more diverse and offer manufacturers more

opportunities to optimize production.

Choosing the right cast iron casting

process is a crucial step in enhancing product quality and production

efficiency. Understanding the characteristics and applications of various

processes, combined with practical considerations, allows manufacturers to

optimize workflows, reduce costs, and meet customer needs. In the future, as

technology continues to advance, casting processes will become increasingly

intelligent and environmentally friendly, unlocking even greater potential for

industrial manufacturing.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh