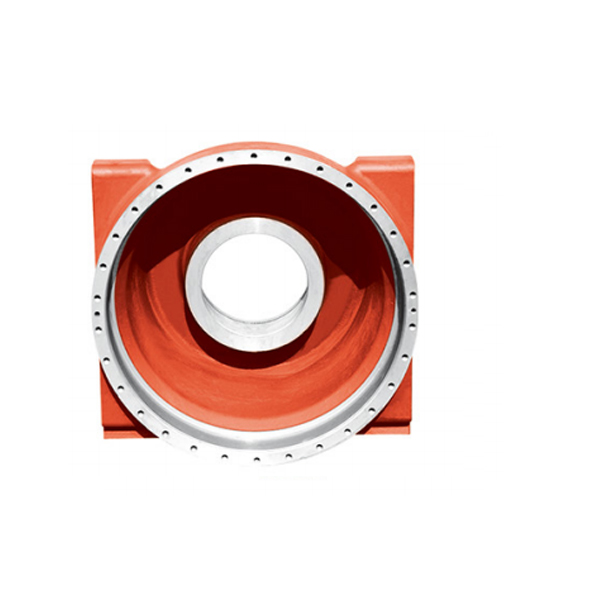

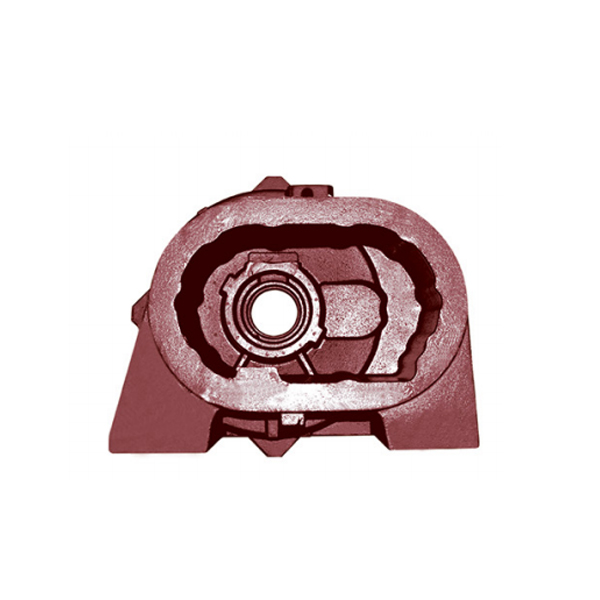

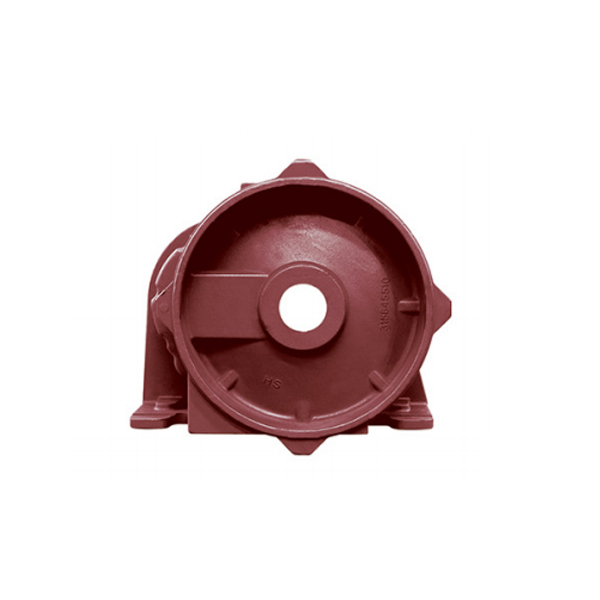

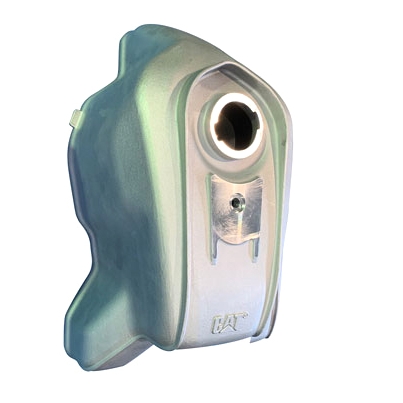

Customized cylinder head castings

Iron Valley provides you with high-precision customized cylinder head castings, designed specifically to meet the high-performance requirements of various engines. As the core component of the engine, cylinder head castings undertake multiple functions such as sealing the cylinder, installing valve mechanisms, forming combustion chambers, and cooling water channels. We adopt advanced casting technology and strict quality control system to ensure that every cylinder head casting has excellent precision, durability, and reliability.

Introduction

Customizable

Transportation modes:Including sea transportation, railway transportation, and road transportation.

Minimum order quantity:Comprehensive evaluation based on actual orders.

Qualification certification: Complete qualifications to ensure reliable quality.

Sales countries:We have provided products to users regions including Asia, Southeast Asia, Europe, North America, and Africa, serving countries such as the United States, Japan, South Korea, France, Germany, Thailand, Vietnam, the United Arab Emirates, and Saudi Arabia. Looking ahead, we eagerly anticipate cooperating with more global buyers.

Overview:

Cylinder head castings are important components in engines. The cylinder head is the cover of the engine and the components that enclose the cylinder, including the water jacket, valves, and cooling fins. It is the installation base of the valve mechanism and also the sealing cover of the cylinder.

Product specifications and parameters

- Material: According to customer needs, we provide a variety of material options such as gray cast iron, alloy cast iron, aluminum alloy, etc.

- Size: Supports customized design, providing precise dimensions based on engine model and specific requirements.

- Weight: The weight may vary depending on the material and size, and the actual production shall prevail.

- Pressure bearing: High strength design that can withstand the enormous pressure of engine operation.

- Working temperature range: Suitable for a wide range of temperature environments, ensuring stable operation of the engine under various working conditions.

- Corrosion resistance: After special treatment, the corrosion resistance of cylinder head castings is improved, extending their service life.

Product features and advantages

- High precision customization: We have advanced CAD/CAM design systems and precision casting equipment, which can provide customized design according to customers' specific needs, ensuring the accuracy and matching of cylinder head castings.

- High performance materials: Made of high-quality casting materials, rigorously screened and tested to ensure that the cylinder head castings have excellent mechanical properties and thermal stability.

- Efficient heat dissipation: Optimized waterway design ensures effective heat dissipation of cylinder head castings, preventing engine overheating and improving engine efficiency and reliability.

- Wear resistant and durable: The surface of the cylinder head casting, which has undergone special treatment, has excellent wear resistance and can resist friction and wear of components such as valves and pistons, extending its service life.

- Easy to install and maintain: The design of cylinder head castings takes into account the convenience of installation and maintenance, ensuring that customers can easily replace and repair them during use.

Application Fields and Cases

Our cylinder head castings are widely used in various fields such as automobiles, ships, construction machinery, agricultural machinery, etc. Here are some successful cases:

- In the automotive field, we provide customized cylinder head castings for multiple well-known car manufacturers, which are applied in high-performance engines to improve engine output power and fuel economy.

- In the field of shipbuilding, we provide corrosion-resistant and high-temperature resistant cylinder head castings for large ships to ensure stable operation of ship engines in harsh marine environments.

- In the field of construction machinery, high-strength and wear-resistant cylinder head castings are provided for excavators, loaders and other construction machinery, which improves the work efficiency and reliability of construction machinery.

Customized processes and services

- Requirement communication: Conduct in-depth communication with customers to understand specific requirements and expectations.

- Design confirmation: Based on customer requirements, conduct CAD/CAM design and provide design solutions for customer confirmation.

- Production and manufacturing: Advanced casting technology and equipment are adopted, and production is strictly carried out according to the design plan.

- Quality inspection: Conduct strict quality inspections on each cylinder head casting to ensure compliance with customer requirements.

- Delivery acceptance: Deliver qualified cylinder head castings to customers and provide corresponding technical support and after-sales service.

FAQ

Q1:How do you ensure your product quality?

Photos

-

Reducer Housing Manufacturer | Custom Cast Iron & Steel Gear Reducer Casings

-

Industrial Gearbox Manufacturer | Custom Cast Iron/Steel Gearboxes for Mining & Wind Energy

-

High-Performance Gearbox End Caps | Industrial-Grade Sealing Solutions for Gearboxes

-

Electric Motor Castings Manufacturer | Custom Aluminum & Iron Motor Housings

-

High-Quality Taper Bushed Pulleys | SPB/SPA Series | Customizable & Durable

-

Gantry Castings Manufacturer | Custom Steel & Iron Gantry Frame Castings

-

Large Castings Manufacturer | Heavy Iron & Steel Casting Parts Supplier

-

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh