Investment Casting (Lost Wax Casting)

2024-11-15 08:42:24 hits:0

Investment Casting (Lost Wax Casting)

When it comes to investment casting of

metal parts manufacturing factors such as design requirements, cost, and

feasibility to manufacture dictate which casting process is most suitable to manufacture

a product. This article describing investment casting is intended to help you

make an informed casting decision.

Investment casting produces precise

components while minimizing material waste, energy, and subsequent machining.

It can also ensure the production of very intricate parts. This makes the

investment casting process quite useful to design engineers.

The goal is to understand what is meant by

investment casting. So, What exactly is the investment in “investment” casting?

The term “invested” historically carries the meaning of “clothed” or

“surrounded.” Investment casting employs a shell made of ceramic,

plaster, or plastic that is formed around a wax pattern. The wax pattern is

melted and removed in a furnace and metal is poured into the shell to create

the casting.

What is investment casting used for? Let’s

break down the investment casting production process for a greater

understanding:

The Investment Casting Process

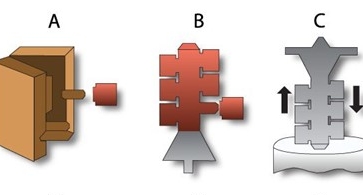

A. Creating The Pattern

- It utilizes a pattern with the same details as the finished

part, except that there is an allowance for thermal contraction (i.e.

shrinking).

- Patterns are typically made of wax using a metal injection

die.

B. Mounting The Wax Patterns And

Creating The Tree

- Once a wax pattern is produced, it is assembled with other wax

components to form the gate and runner metal delivery system.

- Depending on the size and configuration of the desired finish

component, multiple wax patterns may be processed using a single tree.

C. Creating The Mold Shell

- The entire wax pattern assembly is dipped in a ceramic slurry,

covered with sand stucco, and allowed to dry.

- Cycles of wet dipping and subsequent stuccoing are repeated

until a shell of the desired thickness is created. That thickness is

partly dictated by product size and configuration.

- Once the ceramic shell has dried, it becomes sufficiently

strong to retain the molten metal during casting.

D. Wax Removal

- The entire assembly is placed in a steam autoclave to melt away

most of the wax.

- Any remaining wax soaked into the ceramic shell is burned out

in a furnace. At this point, the residual wax pattern and gating material

have been completely removed and the ceramic mold remains with a cavity in

the shape of the desired cast part.

- This high-temperature operation also increases the strength and

stability of the ceramic material. In addition, it helps to minimize the

reaction of the shell and metal during pouring.

E. Melt And Cast

- The mold is preheated to a specific temperature and filled with

molten metal, creating the metal casting.

- Nearly any alloy can be produced using this process.

Either air melting or vacuum melting may be employed as dictated by the

alloy chemistry. Vacuum melting is utilized mainly when reactive elements

are present in the alloy.

F. Final Operations

- Once the casting has cooled sufficiently, the mold shell is

broken away from the casting in a knockout operation.

- The gates and runners are cut from the casting, and if

necessary, final post-processing sandblasting, grinding, and machining is

performed to finish the casting dimensionally.

- Non-destructive testing may include fluorescent penetrant,

magnetic particle, radiographic, or other inspections. Final dimensional

inspections, alloy test results, and NDT are verified prior to shipment.

Advantages Of Investment Casting Process

Size Range:

Although most investment castings are

small, the investment process can produce castings weighing more than 1,000

pounds. This capability is limited to a relatively small number of investment

casters and requires special expertise in handling. Most cast parts fall in the

ounces to a 20-pound range.

Versatile And Intricate Shapes:

Investment casting provides consistent and

repetitive close tolerances along with intricate passages and contours. Many of

these configurations are impossible to produce. For example, where machine

tools cannot reach. Achieving net-shape or near-net-shape cast components can

dramatically reduce post-cast processing costs.

Investment casting is a good alternative to

weldments or fabricating. Many components can be combined into a single

casting. The more that are combined, the better the manufacturing efficiency.

Converting multi-piece components to a single investment casting typically

delivers more dimensional accuracy and reduced part complexity.

Accurate And Smooth Surfaces:

The ceramic shell used is built around

smooth patterns produced by injecting wax into a polished aluminum die. A 125

micro finish is standard, and even finer finishes are not uncommon.

Investment castings contain no parting line

because only one mold is used rather than two half molds (such as in the case

of sand

casting). Standards for surface blemishes and cosmetics are discussed and

agreed upon with the customer based on the function.

Below is a comparison of relative surface

finishes that can be expected from various casting process:

|

Casting Process |

RMS Range |

|

Die |

20 – 120 |

|

Investment |

60 – 200 |

|

Shell Mold |

120 – 300 |

|

Centrifugal – Standard tooling |

400 – 500 |

|

Centrifugal – Permanent Mold |

20 – 300 |

|

Static – Permanent Mold |

200 – 420 |

|

Normal Non-Ferrous Sand |

300 – 560 |

|

Normal Ferrous Green Sand |

560 – 900 |

Dimensional Accuracy:

Typically, “standard” investment tolerances

are +/-0.010” for the first inch and +/- 0.004” for each succeeding inch.

The design phase can result in a drawing

that reduces or even eliminates previous machining requirements to produce the

same part.

The cost of any part increases in

proportion to the preciseness of its dimensional requirements. Whether if it’s

castings machined parts or fabrications. A close design review will permit

modification to tolerances, undercuts, blind holes, etc. to allow higher

production yields and lower piece costs. If closer than cast tolerances are

necessary, the machining required for investment casting will be less than

conventional castings or fabricated components.

Quality And Integrity:

Casting integrity is an important feature

of the process. Investment casting has a long history of serving demanding

sectors such as gas turbine

engine, petroleum, chemical, defense, and

medical.

Considerations When Using Investment

Casting

Tooling Cost:

For low quantity requirements, it may be

more expensive than other methods if permanent tooling is pursued. For those

applications, SLA or

printed patterns may be a cost-effective alternative (even for a quantity of

one).

Initial costs are another key factor when

determining whether investment casting brings the greatest value. The

investment cast tool usually consists of multiple parts fitted together to

produce the complex components. This “front end” cost is not insignificant but

can be easily offset by the lack of subsequent machining and/or fabrication.

Size Limitations:

It’s possible to create investment castings

in a range of sizes. There is an upper limit on that range, which is less than

other shaped technologies like sand casting.

Very Small Structures:

Investment casting is an excellent choice

for thin-walled applications, but very small internal shapes that use cores can

present challenges. Holes typically cannot be smaller than 1/16” (1.6mm) or

deeper than 1.5 times in diameter.

Timing:

The multi-step investment casting process

is more time consuming than other processes. The processing time can be shorter

than other alternatives.

Previous: What is Ductile Iron?

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh