What is Ductile Iron?

2024-11-14 11:05:50 hits:0

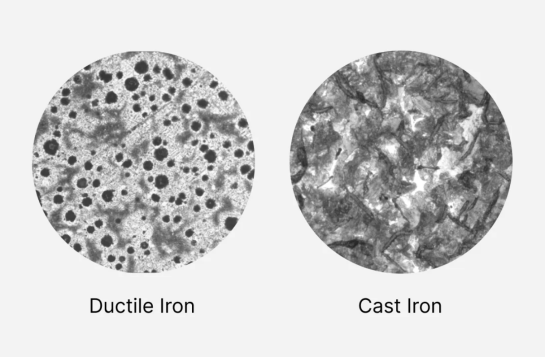

Ductile iron, also known as nodular cast iron or spheroidal graphite iron, and SG iron, is a type of cast iron material that exhibits exceptional mechanical properties. Unlike traditional cast iron, ductile iron improves the material’s ductility and toughness by modifying the shape of the graphite within the iron. This makes it an essential engineering material used in industries such as automotive, machinery, and construction.

1. Composition of Ductile Iron

The primary components of ductile iron are similar to those of regular cast iron, consisting mainly of iron, carbon, and silicon. However, during the production process, small amounts of rare earth elements (such as lanthanum and gadolinium) and other alloying elements (like copper and chromium) are added. These elements help modify the structure of the graphite, transforming it into a spherical shape, rather than the flaky or dendritic forms typically found in traditional cast iron. This transformation significantly enhances the mechanical properties of the material.

2. The Change in Graphite Structure

In regular cast iron, the graphite is typically flake-like or dendritic, which tends to promote crack propagation under stress, making the material brittle. In contrast, in ductile iron, the graphite is spheroidized through a process called "graphite spheroidization" or "nodulization." The spherical shape of the graphite helps to distribute stress more evenly, preventing cracks from spreading and thus improving the iron's toughness and strength.

3. Advantages of Ductile Iron

- Ductile iron offers several significant advantages over both traditional cast iron and steel:Excellent Strength and Toughness: Ductile iron has high tensile strength and yield strength, along with superior impact resistance and wear resistance.

- Good Machinability: Although harder than regular cast iron, ductile iron is still easy to machine and can be processed into complex shapes, meeting the demands of precision engineering.

- Corrosion Resistance: When alloyed with specific elements, ductile iron exhibits good resistance to corrosion, making it suitable for use in harsh environments.

- Vibration Damping: The spherical graphite structure effectively absorbs vibrations, which is why ductile iron is often used in parts that require good vibration-damping properties.

4. Applications of Ductile Iron

Due to its outstanding performance, ductile iron is widely used across various industries, particularly in automotive, machinery manufacturing, and construction. Some common applications include:

- Automotive Industry: Ductile iron is used in manufacturing critical automotive components such as engine blocks, brake discs, and drive shafts.

- Piping Systems: Ductile iron pipes are widely used in municipal infrastructure for water, sewage, and gas lines due to their strength and resistance to corrosion.

- Machinery: Many machinery parts, such as machine bases, brackets, and other load-bearing components, are made from ductile iron for its durability and strength.

- Construction: In the construction industry, ductile iron is used for making pipe fittings, structural supports, and other essential parts.

5. The Future of Ductile Iron

With ongoing technological advancements, the production processes and application scope of ductile iron continue to evolve. For example, improvements in spheroidization techniques have made the graphite structure more uniform, further enhancing the material's mechanical properties and corrosion resistance. Additionally, ductile iron's potential applications in emerging fields like electric vehicles and smart manufacturing are garnering increasing interest.

In conclusion, ductile iron, with its exceptional properties, has become an indispensable material in modern industry, and its future applications remain promising.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh