Ductile Iron Pipe With Special Coating

Special coated ductile iron pipes are widely used in urban water supply, drainage, gas transportation and other fields. Its excellent anti-corrosion performance and service life make it an ideal choice in these fields. Especially in scenarios that require high anti-corrosion performance, high pressure, or special water quality requirements, special coated ductile iron pipes are indispensable.

Introduction

Customizable

Transportation modes:Including sea transportation, railway transportation, and road transportation.

Minimum order quantity:Comprehensive evaluation based on actual orders.

Qualification certification: Complete qualifications to ensure reliable quality.

Sales countries:We have provided products to users regions including Asia, Southeast Asia, Europe, North America, and Africa, serving countries such as the United States, Japan, South Korea, France, Germany, Thailand, Vietnam, the United Arab Emirates, and Saudi Arabia. Looking ahead, we eagerly anticipate cooperating with more global buyers.

With the increasing demand for the quality of ductile iron pipes, various special anti-corrosion coatings for cast iron pipes have emerged. Special coated ductile iron pipes are a type of ductile iron pipe coated with a special coating on the inner or outer surface of the pipeline. This type of pipeline not only maintains the original high strength, toughness, and corrosion resistance of ductile iron pipes, but also further enhances their anti-corrosion performance and service life through special coatings.

1. Cement mortar+epoxy resin lining

According to market demand, Tiegu has launched a new internal anti-corrosion coating: cement lining+epoxy resin lining. This sealing layer uses a two-component epoxy coating that does not contain any organic solvents, does not release any pollutants into the water body, and can effectively inhibit the precipitation of alkaline substances in the cement lining, thereby ensuring safer and more hygienic water quality during transportation. Due to the smoother texture of cement and epoxy resin lining compared to cement lining, it reduces water head loss during pipeline operation and saves pipeline operating costs. The recommended thickness for the sealing layer is 100 μ m; The application scope includes drinking water, direct drinking water, and soft water for industrial special purposes. It has the advantages of solvent-free epoxy coating, 100% solids, no volatile organic compound emissions, no ecological pollution, low shrinkage rate of cured paint film, moderate curing speed, good adhesion to cement, smooth, dense, hard coating, low friction resistance, high conveying capacity, insensitive to moisture and humidity, non-toxic coating after curing, and a service life of up to 100 years.

2. Epoxy ceramic lining

Description:Epoxy ceramic is a new type of anti-corrosion coating for the inner lining of ductile iron pipes. It is a new process of naturally curing epoxy ceramic coating on the cement inner wall of cast iron pipes by mechanical spraying or manual brushing. It is suitable for water supply and drainage projects that transport sewage, reclaimed water, and drinking water.

Advantages: The inner lining of epoxy ceramic ductile iron pipes is achieved by coating the ductile iron pipes with epoxy ceramics, resulting in a dense, smooth, ceramic like, firmly bonded, uniformly thick inner lining layer that is resistant to seawater, corrosion-resistant, and has excellent electrical insulation properties. Resistant to corrosion from marine organisms and microorganisms, it is the preferred choice for surface anti-seepage and anti-corrosion coatings, with a lifespan of over 100 years. Smooth surface, low wear resistance, and excellent hydraulic performance. The inner lining is hygienic and can be used to transport drinking water, ensuring reliable hygiene.

3. Polyurethane inner coating

Description:The polyurethane lining of ductile iron pipes is made by spraying two-component, solvent-free, 100% solid content polyurethane material. The coatings used are divided into ordinary polyurethane and high-density polyurethane. This lining has excellent anti-corrosion performance and wear resistance, and shows high resistance to different transportation media (such as drinking water/wastewater/soft water/industrial water/strong corrosive solutions, etc.). It is suitable for water supply projects of all water qualities from soft water to hard water, such as municipal sewage, and the transportation of certain industrial wastewater. It can be used for water supply projects, as well as for transporting wastewater with high solid particle content, industrial water, and surface water, and for environments with high flow rates due to large inclination angles during pipe installation.

Product features: 100% solid content, no volatile organic compounds, in compliance with environmental requirements; It has excellent corrosion resistance, wear resistance, and impact resistance, and can be used to transport wastewater with high solid particle content, industrial water, and surface water, as well as environments with high flow rates due to large inclination angles during pipe installation; Smooth surface with low wear resistance and excellent hydraulic performance; The inner lining is hygienic and can be used to transport drinking water, ensuring reliable hygiene; The coating does not scale, the water quality will not be contaminated or oxidized by microorganisms in the water, and there will be no secondary pollution. It can ensure that the permanent water delivery capacity and water cleanliness remain unchanged.

4. Polyurethane outer coating

Under normal conditions, ductile iron pipes are coated with standard internal and external anti-corrosion coatings, but polyurethane external coatings can be chosen for burial in highly corrosive soil or in highly corrosive transport water. Mainly used for external anti-corrosion of pipelines in highly corrosive soil environments, such as crossing wet areas such as seawater, salt alkali, swamps, etc; Is the resistivity less than 750 Ω? Acidic peat soil contains garbage, oxide skin, slag, or soil contaminated with wastewater or industrial waste liquids, or requires the use of special reinforced protective layers.

5. Zinc aluminum alloy outer coating

Description:Usually, ductile iron pipes are coated with 130 g/m2 or 200 g/m2 zinc coating for external anti-corrosion, which can effectively protect ductile iron pipes from general types of soil corrosion. However, under strong corrosion conditions, the service life of ductile iron pipes is shortened. By using Tiegu ductile iron pipes coated with a 400g/m2 zinc aluminum alloy outer layer, they can adapt to over 90% of soil corrosion types and increase the pipeline protection period by 3-4 times.

Application areas include: damp areas such as ponds, marshes, swamps, and low-lying areas; Saline alkali land; Clay with poor breathability; Areas with stray currents such as power rails and high-voltage lines nearby; Industrial and agricultural parks such as chemical plants, waste treatment facilities, thermal power plants, dairy farms, etc. in low resistivity areas such as metal mining areas.

6. FAQ

To help you better understand our products and services, we have compiled some frequently asked questions and answers. If you have any questions or need further assistance during your visit, please feel free to contact our customer service team.

Q1: What does your company do?

Our company is a supplier specializing in the steel casting industry. We not only have independently developed and produced product lines, but also have the ability to integrate high-quality domestic supplier resources in China. We have established long-term cooperative relationships with multiple reputable and strong suppliers. We provide global users with a wide range of high-performance products, efficient logistics and delivery, and high-quality customer service.

Q2: How do you ensure product quality?

A: We strictly adhere to international standards and industry norms for production and quality control. All products undergo rigorous quality testing to ensure they meet customer requirements and expectations. Additionally, we provide a comprehensive quality assurance system and after-sales service to ensure your purchase is worry-free.

Q3: How can I obtain information about your products?

A: You can browse our product catalog on our official website to learn more about our products. If you need more detailed product information or samples, please contact our team, and we will provide you with professional product consultation and sample services.

Q4: What customization services do you offer?

A: We offer a full range of customization services, including product specifications, materials, packaging, and more. If you have specific needs or requirements, please contact our customer service team, and we will provide you with personalized customization solutions based on your needs.

Q5: How can I establish a cooperation relationship with you?

A: If you are interested in our products or services and wish to establish a cooperation relationship with us, you can fill out the online form , leave your information, or directly contact our team. We will provide you with detailed cooperation processes and conditions, and arrange professional sales personnel to communicate with you.

Q6: What after-sales services do you provide?

A: We provide comprehensive after-sales services, including product consultation, technical support, repair and replacement, etc. If you encounter any problems or need help during use, please feel free to contact our customer service team. We will be happy to provide you with quality service and support.

Q7: How can I contact you?

A: You can contact us through the following methods:

Phone Number:86 152 5613 5588

E-mail:karvin@tiegu.net

Add.:Room 410-946, International Business Center, Haikou Cross-border E-commerce Industrial Park, Hainan Province

Tiegu (Hainan) International Trade Co., LTD

You can also fill out the online form and leave your contact information, and we will contact you within 12 hours

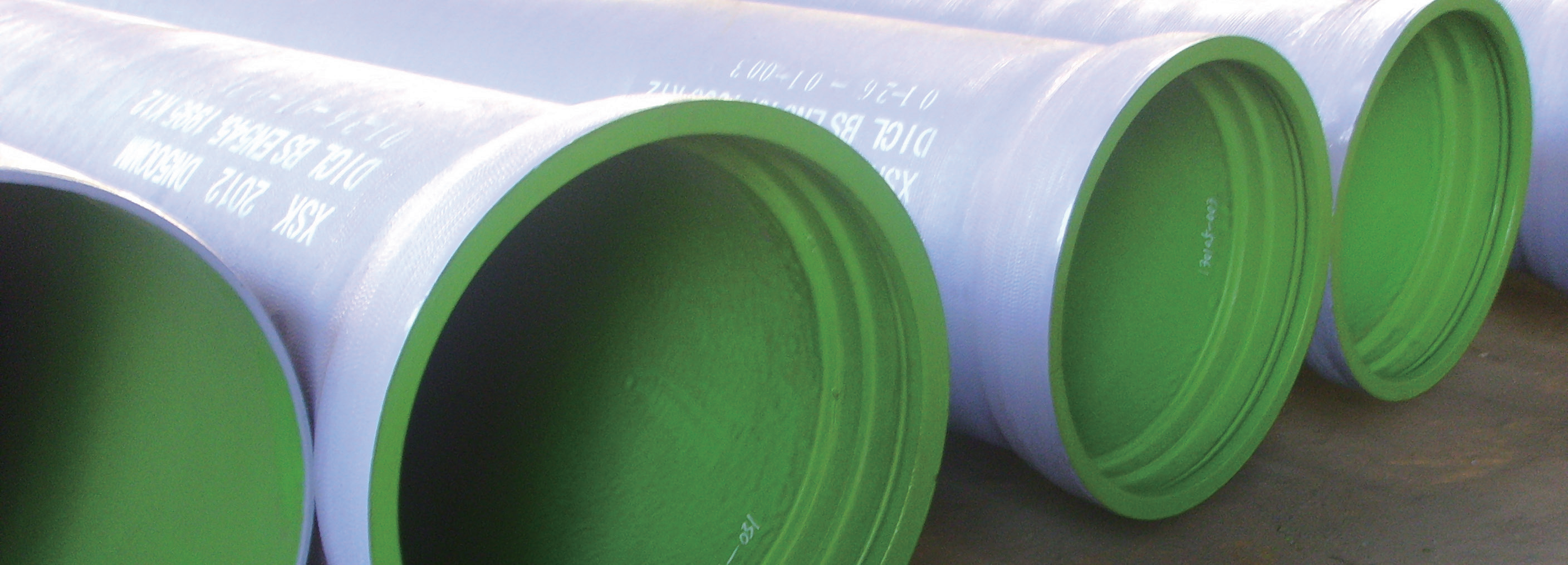

Photos

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh