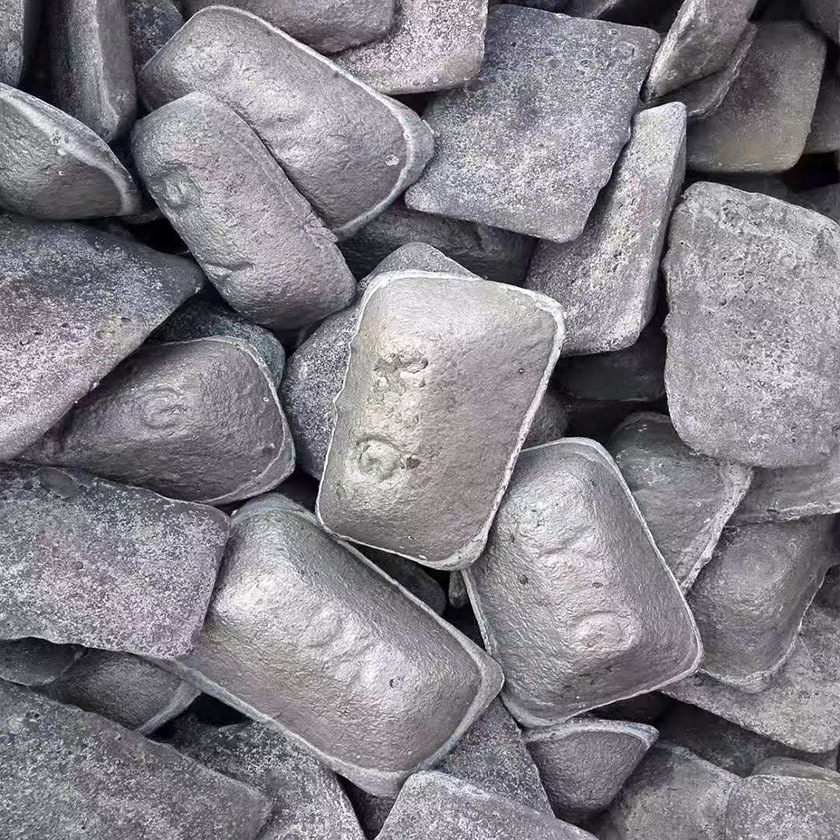

Iron for ductile iron casting

If you are interested in our products, you can contact us. Phone+86 152 5613 5588 Email: zbw@tiegu.net

Introduction

Customizable

Transportation modes:Including sea transportation, railway transportation, and road transportation.

Minimum order quantity:Comprehensive evaluation based on actual orders.

Qualification certification: Complete qualifications to ensure reliable quality.

Sales countries:We have provided products to users regions including Asia, Southeast Asia, Europe, North America, and Africa, serving countries such as the United States, Japan, South Korea, France, Germany, Thailand, Vietnam, the United Arab Emirates, and Saudi Arabia. Looking ahead, we eagerly anticipate cooperating with more global buyers.

Ductile iron is a type of cast iron material with high strength, toughness, corrosion resistance, and wear resistance. Its performance is superior to other cast iron materials, such as ductile iron and white cast iron, and therefore it has been widely used in the industrial field. Ductile iron products play an important role in fields such as petroleum, chemical, hydropower, and mechanical manufacturing.

The production process of ductile iron is to put raw materials such as iron ore, iron ore sand, coke, and limestone into a high-temperature furnace, add inoculants, and make the molten iron form spherical shapes during the flow process. This process can form a spherical structure in the molten iron during the cooling process, thereby improving the strength and toughness of the material. The mechanical and physical properties of ductile iron are superior to other cast iron materials.

Ductile iron products have high strength and toughness, and can withstand significant pressure and impact loads. Therefore, in the field of petrochemicals, ductile iron is widely used in the manufacture of key equipment such as pressure vessels and reaction vessels. In addition, ductile iron is also used to manufacture equipment such as pipelines, valves, pumps, as well as components of mechanical equipment such as water turbines and compressors.

In the field of hydropower, ductile iron is used to manufacture key components of equipment such as water turbines and generator sets, such as runners and blades. Due to its high strength and toughness, ductile iron can withstand the impact load of water flow, thus improving the efficiency and reliability of hydropower equipment.

In the field of mechanical manufacturing, ductile iron is used to manufacture various mechanical parts such as gears, bearings, pulleys, etc. Due to its good wear resistance and corrosion resistance, ductile iron can improve the service life and reliability of mechanical parts.

Compared with other materials, ductile iron has a higher cost-effectiveness. It has good mechanical and physical properties, as well as a simple production process and low cost. However, ductile iron also has some limitations, such as high density, which is not conducive to lightweight applications.

Photos

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh