Engines are crafted through a combination of casting and machining procedures. Let's take a closer look:

Casting:

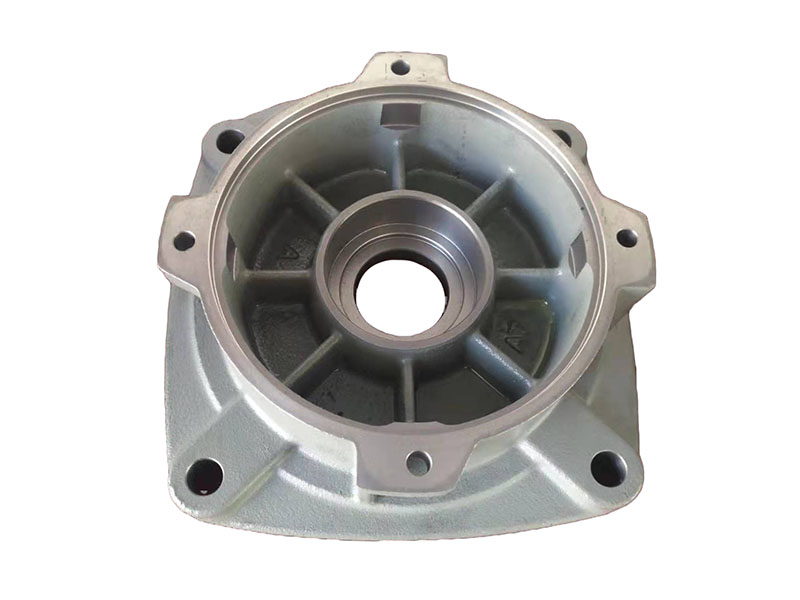

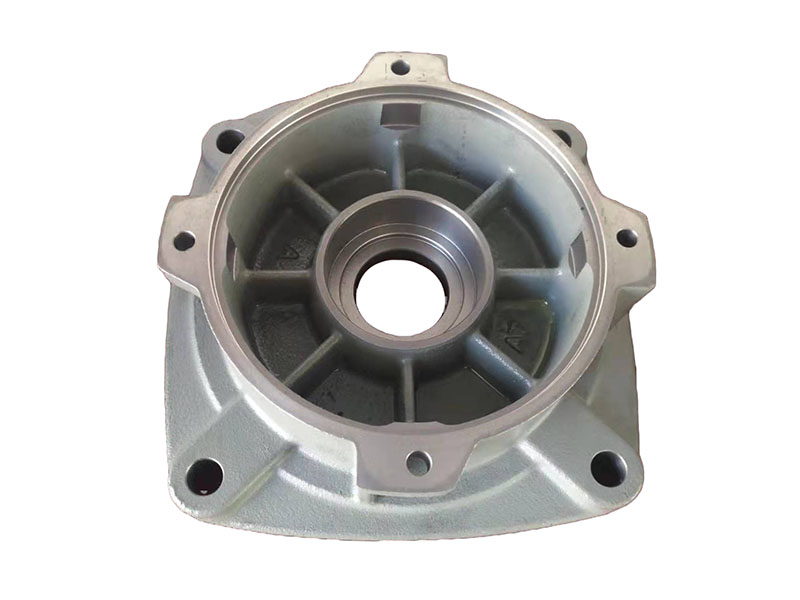

A significant number of engine parts, like the cylinder block, cylinder head, and crankcase, are commonly fabricated using the casting technique. The casting method enables the creation of intricately - shaped components featuring internal cavities and channels, which would be extremely challenging to obtain via other manufacturing means. Molten metal, typically cast iron or an aluminum alloy, is poured into a mold. As it cools and solidifies, it takes on the shape of the intended component. This approach is well - suited for large - scale production and can satisfy the structural demands of engine components.

Machining:

Once the casting process is complete, the majority of engine components necessitate machining operations. These operations are crucial for attaining the required dimensional precision, surface smoothness, and proper fit. Machining techniques encompass turning, milling, drilling, grinding, and honing. For instance, the cylinder bores within the cylinder block must be machined to an exact diameter and a specific surface finish to ensure a seamless fit with the pistons. The crankshaft also demands high - precision machining to guarantee its rotational accuracy and the correct fit of the bearings. Moreover, numerous engine parts have mating surfaces that need to be machined to ensure effective sealing and proper assembly.

In conclusion, the manufacturing of engines integrates both casting and machining to yield top - notch components that adhere to the stringent performance and reliability standards of engines. TIEGU, a professional foundry, specializes in the casting process. We possess advanced casting facilities and a team of skilled professionals. Whether it's the casting of cylinder blocks, cylinder heads, or other engine components, TIEGU is committed to providing high - quality casting services, leveraging our expertise to contribute to the production of high - performance engines.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh