What Are the Examples of Investment Casting Products?

2025-04-02 17:04:46 hits:0

When aerospace engineers design turbine blades with 0.1mm cooling channels or medical teams develop biocompatible hip implants, investment casting becomes the enabling technology. This 5,000-year-old process continues pushing manufacturing boundaries in aerospace, medical, and industrial sectors through its unique precision forming capabilities.

I. Aerospace

In aircraft engines, investment casting demonstrates irreplaceable technical advantages:

GE9X single-crystal turbine blades: Made from nickel-based superalloy CMSX-4 with 95% columnar grain structure via directional solidification, capable of stable operation over 10,000 flight cycles in 1200℃ gas environments.

Combustion chamber liners: MCrAlY-coated cobalt-chromium alloy with CT4 precision (±0.15mm/25mm) ensures gas sealing and thermal fatigue resistance.

II. Medical

Medical implant manufacturing demands extreme material purity and surface properties:

Cobalt-chromium hip implants: Achieve 99.99% metal purity via vacuum casting, with porous Ti plasma spray surfaces (Ra1.6μm) promoting bone cell growth and 900MPa tensile strength (3x human bone).

Titanium spinal implants: Direct casting creates trabecular structures matching natural bone density, avoiding machining-induced stresses.

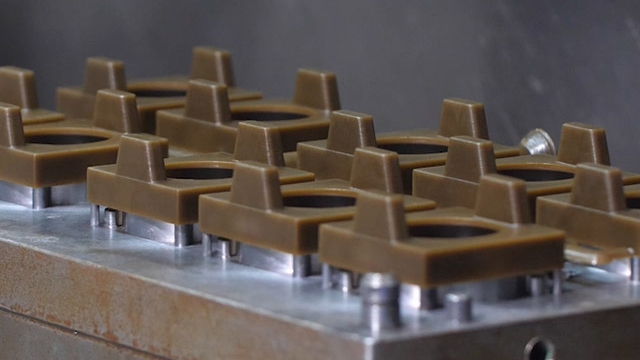

III. Industrial Equipment

In harsh industrial environments, investment casting excels in temperature/corrosion resistance:

Hastelloy C-276 valves: Integrally cast for 200℃ sulfuric acid resistance with <0.01mm/year corrosion rate, reducing welding requirements through one-piece flange design.

Nickel-aluminum-bronze propellers: 0.5mm thin-wall structure optimizes hydrodynamic performance, achieving 50,000+ fatigue cycles in offshore platforms.

IV. Luxury Goods

In luxury manufacturing, investment casting combines artistry with functionality:

18K gold jewelry settings: Lost-wax casting forms 0.1mm diamond prongs with 95% material utilization and Ra0.8μm mirror finishes.

Stainless steel watch cases: One-piece 316L alloy casting provides 100m water resistance while enabling skeletonized movement designs.

V. Energy Sector

For clean energy equipment, investment casting delivers critical support:

Nuclear reactor components: Zirconium alloy castings withstand 300℃ coolant and radiation environments, with integrally formed fuel rod guide tubes ensuring operational safety.

Wind turbine bearings: High-strength steel castings with internal lubrication channels maintain reliability across -40℃ to 50℃ temperature ranges over 10 million cycles.

Why Choose Investment Casting?

Unique advantages include:

✅ Complex geometries: Internal channels impossible with other methods

✅ Material purity: 99.99% metal purity via vacuum casting

✅ Surface finishes: Direct casting achieves medical-grade (Ra1.6μm) and consumer-grade (Ra6.3μm) standards

Tiegu's Technological Breakthroughs

As an industry leader, Tiegu has established benchmark cases:

Aerospace: 92% yield rate for Boeing turbine blades

Medical: 50,000+ FDA-approved implants cast annually

Energy: Custom nuclear components for 3 global reactor manufacturers

Ongoing optimization through 3D-printed wax patterns and automated shelling ensures continuous improvement in precision and efficiency.

Conclusion: The Limitless Potential of Investment Casting

From aerospace turbines to luxury watches, investment casting transforms complex designs into functional reality through material science and process innovation. This 5,000-year-old technology continues driving manufacturing to new heights in industries where precision defines performance.

Call to Action

[Contact Us] Learn how Tiegu provides customized solutions for your high-value components

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh