I. What is the crankshaft?

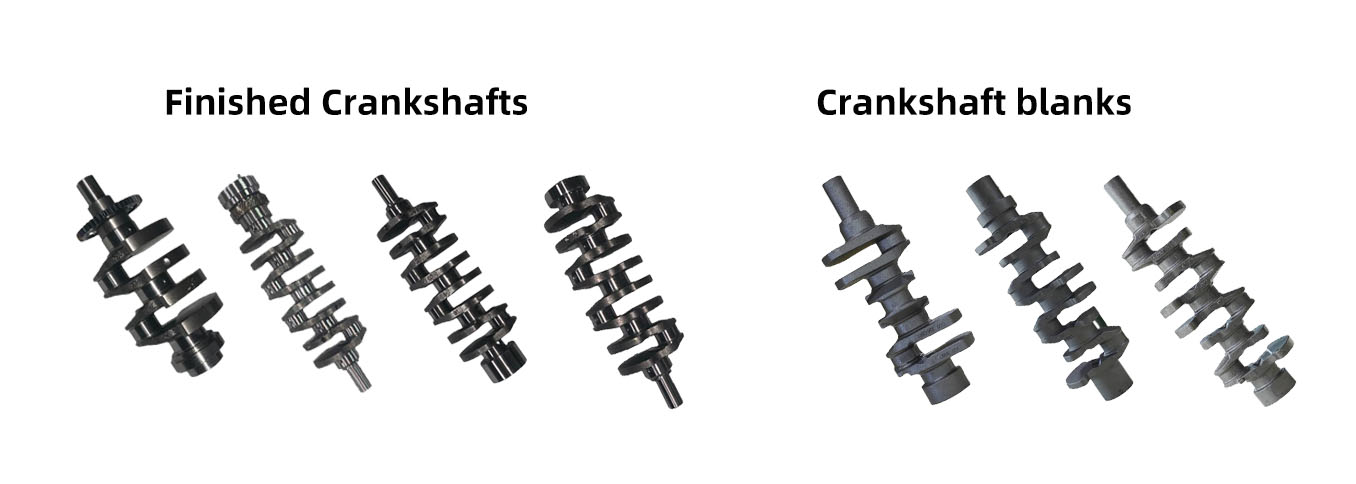

A crankshaft is a precision-engineered mechanical component that converts reciprocating motion from engine pistons into rotational energy. As leading crankshaft manufacturers, we design these critical parts for optimal performance in automotive, marine, and industrial applications. Comprising a series of journals and counterweights, our crankshafts meet ISO 19902 standards for marine use and IATF 16949 for automotive systems.

II. What does a crankshaft do?

This essential engine part performs three key functions:

Transforms linear piston movement into rotational power

Supports connecting rod bearings under extreme pressure

Maintains engine balance through strategically placed counterweights

Our custom crankshafts enhance torque delivery in ship engines crankshaft systems, reducing vibration by up to 30% compared to standard models.

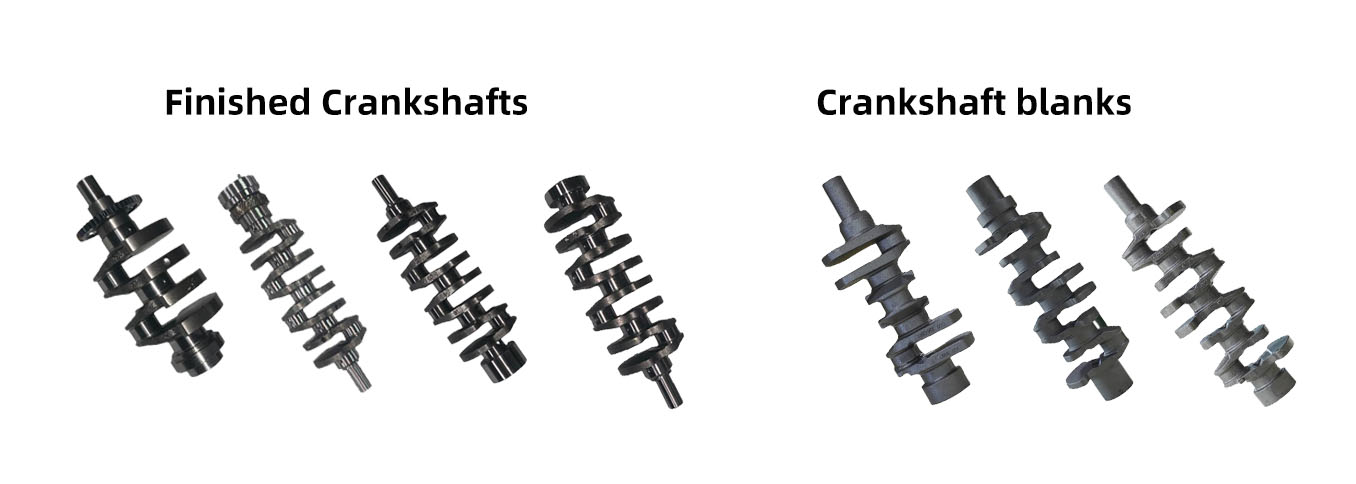

III. Classification and materials of crankshaft castings?

Material Options:

Ductile Iron (QT800-6/QT900-5): Cost-effective with high tensile strength

Forged Steel: Ideal for heavy-duty applications requiring 200+ ksi yield strength

Casting Types:

Cast Crankshafts: Produced via iron mold coated sand casting for complex geometries

Forged Crankshafts: Created through hot forging processes for superior fatigue resistance

IV. What are the 4 parts of the crankshaft?

Main Journals: Support the crankshaft in engine bearings

Connecting Rod Journals: Interface with piston connecting rods

Counterweights: Balance rotational forces during operation

Flywheel Flange: Transmits power to drivetrain components

Our designs incorporate fillet rolling on journal edges, increasing fatigue life by 45%.

V. Factors Affecting Crankshaft Replacement Cost

Cost variables include:

Material Type: Forged steel costs 30-50% more than cast iron

Application Complexity: Marine crankshafts require additional corrosion protection

Customization: Precision balancing for racing engines adds 20-30% to base cost

Certifications: ISO 19902 compliance increases production costs by 15%

VI. What is the casting method of crankshaft?

Our proprietary process includes:

Induction furnace melting with 99.8% purity control

Automated iron mold coated sand casting for ±0.1mm precision

In-line spectrometer analysis every 5 minutes during production

100% ultrasonic testing for internal defects

VII. What is the difference between a camshaft and a crankshaft?

| Feature | Crankshaft | Camshaft |

|---|

| Function | Power transmission | Valve timing |

| Material | Ductile iron/forged steel | Alloy steel |

| Speed | 1,000-6,000 RPM | 500-3,000 RPM |

| Weight | 15-150 kg | 5-25 kg |

| Maintenance | Major overhaul every 100,000 km | Routine inspection every 25,000 km |

VIII. How is a crankshaft made?

Material Selection: Choose cast iron or forged steel based on application

Precision Machining: 5-axis CNC lathes achieve ±0.01mm tolerances

Heat Treatment: Induction quenching increases surface hardness to HRC 55

Surface Finishing: Electropolishing reduces friction coefficient by 18%

Dynamic Balancing: Computer-controlled balancing to G1.0 standards

IX. Choose Tiegu for Your Customized Car Parts

As a trusted crankshaft supply company since 1998, we offer:

Custom crankshafts for Minneapolis, MN, and global markets (shipment within 15 business days)

Direct collaboration with Ohio Crankshaft Company for large-scale projects

In-house pig iron production ensuring stable crankshaft supply at 12% lower cost than competitors

0

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh