Emergency Repair Clamp Supplier | ISO 9001 Certified Pipeline Leak Fixing Solutions

ISO 9001 & GIB9001C certified emergency repair clamps (EN-GJS-500, EPDM seals) for water, gas & oil pipelines. 24/7 support & global delivery.

Introduction

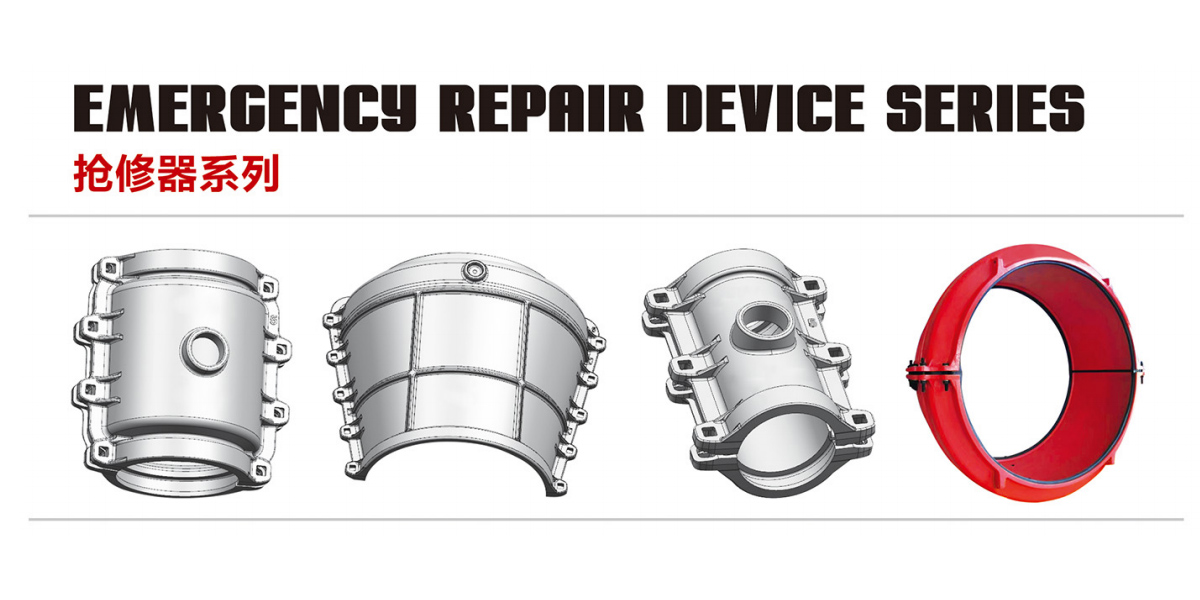

What is an Emergency Repair Clamp?

An emergency repair clamp (also called pipe repair clamp or mechanical leak sealer) is a fast-installation device to stop leaks in pressurized pipelines. Our clamps restore operations within 30 minutes, minimizing downtime for municipal, oil & gas, and industrial systems.

Key Synonyms:

Pipe Leak Repair Clamp

Pipeline Emergency Seal Kit

Ductile Iron Repair Clamp

Technical Specifications

Materials & Compliance

| Component | Specifications | Certifications |

|---|---|---|

| Clamp Body | EN-GJS-500 Ductile Iron | ISO 9001 Production Process |

| Sealing Gasket | EPDM (Ethylene Propylene Diene Monomer) | FDA 21 CFR 177.2600 (Non-toxic) |

| Hardware | A2-70 Stainless Steel Bolts | ISO 3506 Corrosion Resistance |

| Pressure Rating | 16 bar (Water) / 10 bar (Gas) | Hydrostatic Tested (ISO 5208) |

Why Choose Our Emergency Repair Clamps?

✅ Certified Manufacturing

ISO 9001 Quality System: Each clamp undergoes dimensional checks (CMM) and pressure testing.

GIB9001C Compliance: Traceable material records for defense/critical infrastructure projects.

✅ Proven Engineering Design

Universal Fit: Adjustable band width (50-600mm) fits pipes from DN50 to DN600.

Extreme Conditions: Operates from **-30°C to +120°C** (EPDM gasket validated per ASTM D573).

✅ Cross-Industry Reliability

| Industry | Application | Key Feature |

|---|---|---|

| Municipal Water | Repair cast iron/steel pipes in <15 mins | EN 1563-compliant ductile iron |

| Oil & Gas | Seal 10bar gas pipeline leaks | Fire-safe design (tested at 300°C) |

| HVAC | Fix chilled water line leaks | Low-temperature EPDM (ISO 4633) |

Certifications & Testing

ISO 9001: Ensures consistent casting & machining quality.

ISO 14001: Eco-friendly foundry operations (95% sand recycling).

Hydrostatic Tests: 1.5x rated pressure for 30 minutes (no leakage).

Get Certified Samples & Support

🔧 Service Workflow

Submit Requirements: Email pipeline specs (material, diameter, pressure) to zbw@tiegu.net.

Technical Review: Engineers send CAD models & test reports within 2 hours.

Sample Shipment

📩 Contact

Email: zbw@tiegu.net (Subject: [Repair Clamp] + Pipe Type)

Online Form: Request Clamp Quotation

Photos

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh