Reducer Housing Manufacturer | Custom Cast Iron & Steel Gear Reducer Casings

High-strength reducer housings (EN-GJL-250/ASTM A536) with CNC precision machining. ISO 9001 & IATF 16949 certified. Get free samples & CAD models!

Introduction

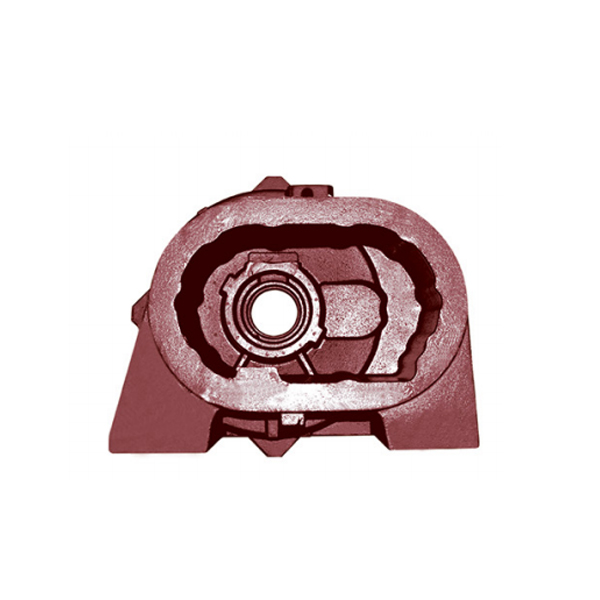

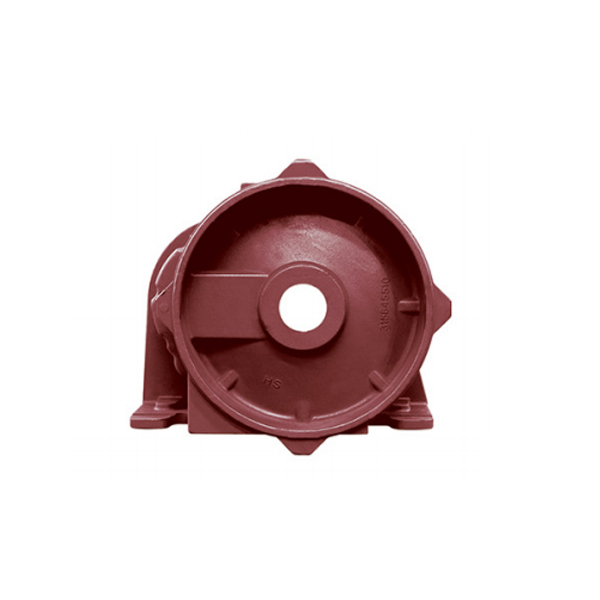

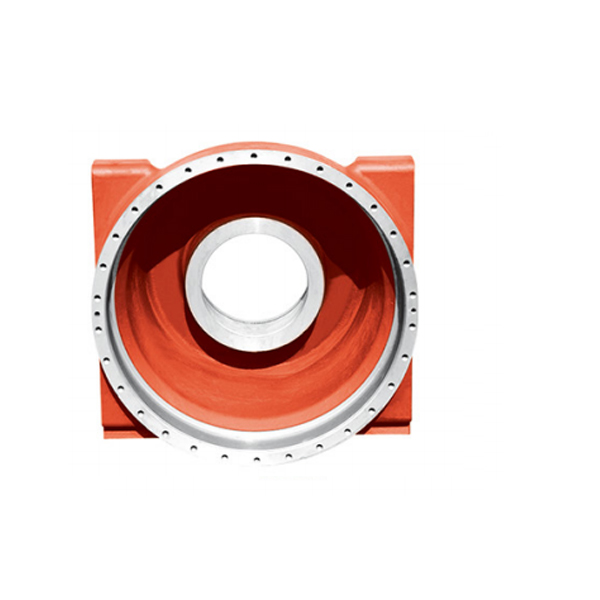

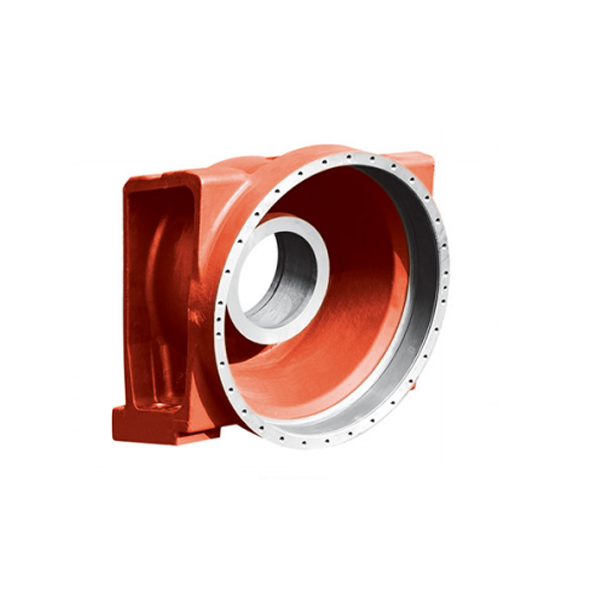

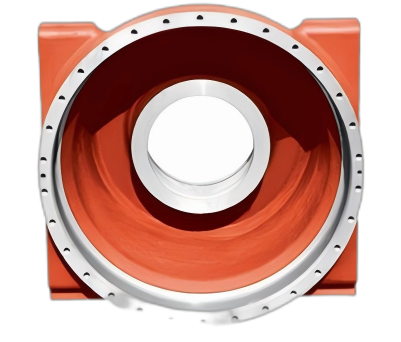

What is a Reducer Housing?

A reducer housing (also called gear reducer casing or speed reducer enclosure) is the structural shell protecting internal gears and bearings in industrial reducers. It ensures precise alignment, lubricant retention, and resistance to shock/vibration in harsh environments like mining, robotics, and wind energy.

Industry Synonyms:

Gear Reducer Casing

Speed Reducer Enclosure

Industrial Reducer Shell

Technical Specifications of Our Reducer Housings

Materials & Casting Process

Cast Iron Housings:

EN-GJL-250 (Tensile Strength ≥250MPa | Hardness HB190-220)

ASTM A536 65-45-12 Ductile Iron (Impact Resistance ≥15J)

Casting Methods:

Resin Sand Casting (±1.2mm Tolerance)

Lost Foam Casting for Complex Geometries

Precision Machining

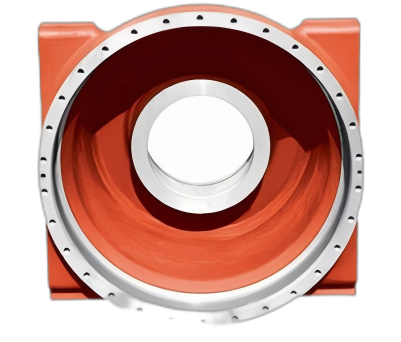

Bearing Seat Accuracy: IT7 Grade (Ra 1.6μm Surface Finish)

Flange Flatness: ≤0.05mm/m (Tested with Laser Scanners)

Hole Position Tolerance: ±0.1mm (5-Axis CNC Machining)

Certifications & Testing

Standards Compliance: ISO 6336 (Fatigue), ISO 20653 (IP67 Sealing)

Quality Control:

100% Spectrometer Material Verification

Helium Leak Test ≤1×10⁻⁶ mbar·L/s

Why Choose Our Reducer Housings?

✅ Vertical Integration from Smelting to Machining

230m³ Blast Furnace: Produces low-sulfur (≤0.02%) molten iron for defect-free castings.

30-Ton CNC Vertical Lathes: Machine reducer housings up to Ø3m diameter.

✅ Proven Performance in Extreme Conditions

Mining Reducers: 20,000+ EN-GJL-250 housings supplied for conveyor drives (MTBF ≥50,000 hours).

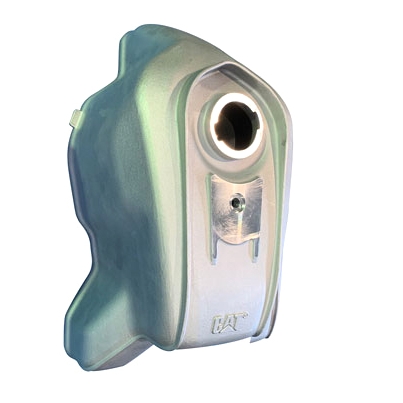

Robotic Reducers: Aluminum housings (ADC12) with 40% weight reduction for 6-axis arms.

✅ Fast Customization & Delivery

15-Day Lead Time for standard designs.

72-Hour Emergency Service: DHL-shipped housings with real-time tracking.

Applications of Reducer Housings

Wind Turbine Yaw Systems: GL-certified EN-GJS-400-18 casings for 5MW+ turbines.

Cement Plant Gear Reducers: High-temperature resistant housings for rotary kilns.

Automotive Assembly Lines: IATF 16949 compliant housings for EV drivetrain test rigs.

Certifications & Global Recognition

Certifications: ISO 9001, IATF 16949, PED 2014/68/EU.

Strategic Partners: Siemens, Bonfiglioli, Nord Drivesystems.

Export Markets: 30% sales to Germany, USA, and Middle East.

Reducer Housing vs. Gearbox Housing: Key Differences

While reducer housings focus on speed reduction units, gearbox housings are used for torque multiplication. We excel in both – Contact Us for cross-industry solutions.

Get Technical Support & Samples

🔧 Professional Service Workflow

Requirement Communication: Provide reducer model, operating conditions, or drawings to receive initial material/process recommendations.

Technical Validation: Our engineering team evaluates requirements and delivers a feasibility report with sample proposals.

Sample Delivery: Physical samples arranged after final confirmation.

📩 Contact Channel

Email: zbw@tiegu.net

Subject Format:

[Technical Inquiry] + Product Nameor[Sample Request] + Company NameRequired Info: Application industry, material specs, annual volume (if any)

Online Form: Submit Requirements Online

Guaranteed Response: Our engineers will reply within 2 hours (business days).

🏭 On-Site Factory Verification

Schedule a Casting & Machining Workshop Tour (including load testing demonstrations) after qualification review.

Photos

-

Industrial Gearbox Manufacturer | Custom Cast Iron/Steel Gearboxes for Mining & Wind Energy

-

High-Performance Gearbox End Caps | Industrial-Grade Sealing Solutions for Gearboxes

-

Electric Motor Castings Manufacturer | Custom Aluminum & Iron Motor Housings

-

High-Quality Taper Bushed Pulleys | SPB/SPA Series | Customizable & Durable

-

Gantry Castings Manufacturer | Custom Steel & Iron Gantry Frame Castings

-

Large Castings Manufacturer | Heavy Iron & Steel Casting Parts Supplier

-

-

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh