Industrial Gearbox Manufacturer | Custom Cast Iron/Steel Gearboxes for Mining & Wind Energy

High-torque gearboxes (EN-GJL-250/ASTM A536) with CNC precision machining. ISO 9001 certified, serving Siemens, Bonfiglioli & global clients. Free sample & CAD!

Introduction

What is a Gearbox?

A gearbox (also called gear case or transmission case) is a sealed mechanical assembly transferring power via gears, widely used in mining, wind turbines, and heavy machinery. Our foundry-to-finish manufacturing ensures low noise, high efficiency, and 20,000+ hour service life.

Key Synonyms:

Gear Case

Transmission Case

Power Drive Unit

Technical Specifications of Our Industrial Gearboxes

Materials & Casting Process

Cast Iron Gearboxes:

EN-GJL-250 (Hardness HB190-220 | Tensile Strength ≥250MPa)

ASTM A536 65-45-12 Ductile Iron (Impact Resistance ≥15J)

Casting Methods:

Sand Casting ±1.5mm Tolerance → CNC Machining (IT7 Accuracy)

Surface Finish: Phosphating (Anti-Corrosion) / Dacro-coating (Aesthetic)

Performance & Certifications

Load Capacity: Up to 50,000 Nm Torque (Tested per ISO 6336)

Protection Class: IP67 (Dust/Waterproof) & IP69K (High-Pressure Wash)

Certifications: ISO 9001, PED 2014/68/EU, GL Wind

Why Choose Our Gearboxes?

✅ Full Vertical Integration

In-House Smelting: 230m³ Blast Furnace → Low-Sulfur (≤0.02%) Molten Iron

Casting & Machining:

5 Casting Workshops (Lost Foam/Resin Sand)

30-Ton CNC Vertical Lathe → Process Ø3m Gear Case Flanges

✅ Customization for Extreme Conditions

Mining Gearboxes: Reinforced Housing for Shock Loads (20,000+ Units Supplied)

Wind Turbine Gearboxes: -40°C Low-Temp Impact Certification (GL Standard)

OEM Adaptability: Modify PCD, Shaft Diameter (Ø50-Ø500mm), & Sealing Types

✅ Fast Global Delivery

15 Days Standard Lead Time

72-Hour Emergency Shipment via DHL/FedEx

Applications & Case Studies

Wind Energy: Supplied 800+ Gear Cases for 4MW Offshore Turbines (European OEM)

Cement Plants: Custom Gearboxes for Rotary Kiln Drives (10-Year Service Contract)

Mining Conveyors: 5,000+ EN-GJL-250 Gearboxes for Belt Drive Systems

Certified Quality Control

Material Testing: Spectrometer Analysis & Charpy Impact Test

Dimensional Inspection: CMM (±0.02mm) & Laser Scanning

Leak Test: Helium Mass Spectrometry (≤1×10⁻⁶ mbar·L/s)

Gearbox vs. Gear Motor: Key Differences

While gearboxes focus on torque/speed conversion, gear motors integrate motors. We provide both solutions – Contact U for system optimization.

Request a Free Gearbox Quote

🔧 Limited Offer:

Free 3D STEP File with Inquiry

5% Discount on First Order Over $30,000

📩 Contact Our Gearbox Experts:

Email: zbw@tiegu.net

Upload Drawings: Get Instant Quote

Photos

-

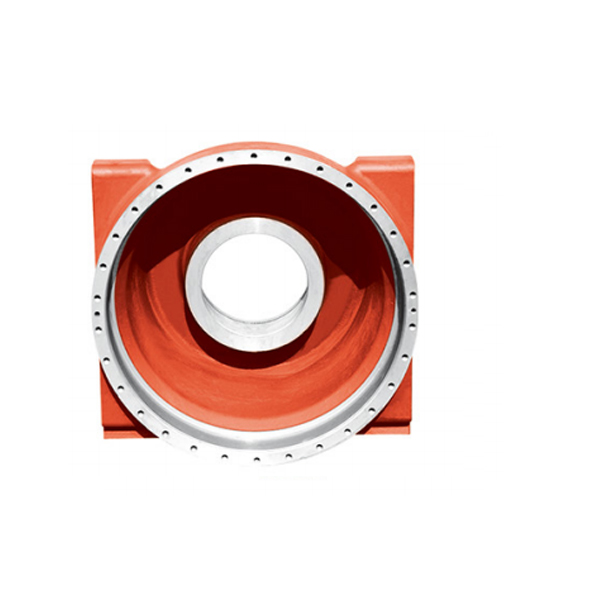

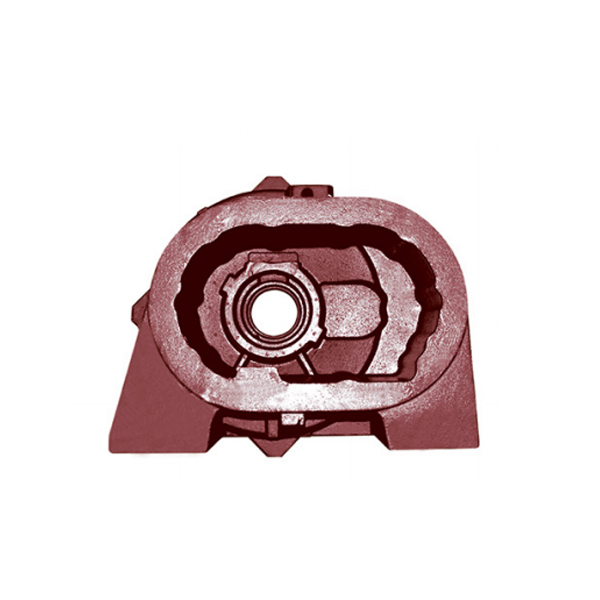

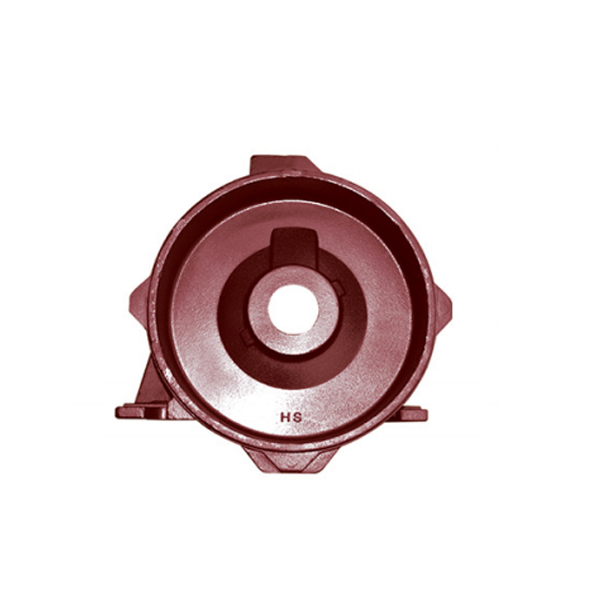

Reducer Housing Manufacturer | Custom Cast Iron & Steel Gear Reducer Casings

-

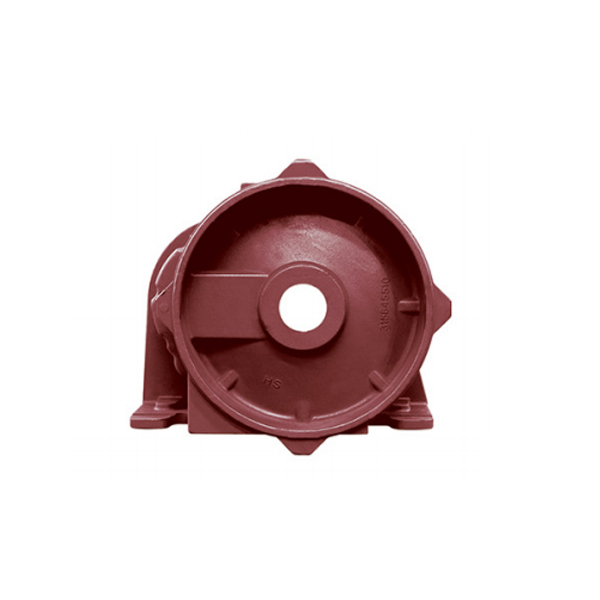

High-Performance Gearbox End Caps | Industrial-Grade Sealing Solutions for Gearboxes

-

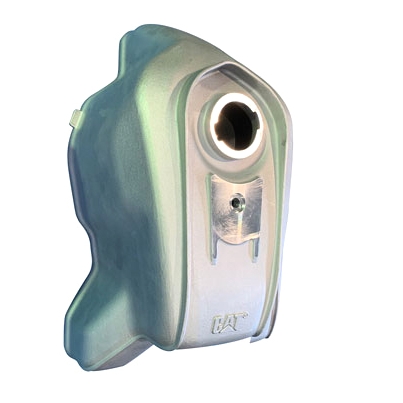

Electric Motor Castings Manufacturer | Custom Aluminum & Iron Motor Housings

-

High-Quality Taper Bushed Pulleys | SPB/SPA Series | Customizable & Durable

-

Gantry Castings Manufacturer | Custom Steel & Iron Gantry Frame Castings

-

Large Castings Manufacturer | Heavy Iron & Steel Casting Parts Supplier

-

-

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh