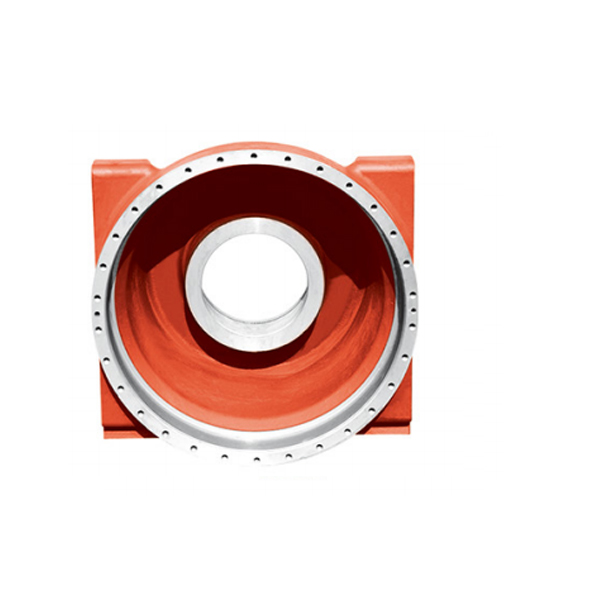

High-Performance Gearbox End Caps | Industrial-Grade Sealing Solutions for Gearboxes

Premium gearbox end caps (also called gearbox end covers or housing end plates) in cast iron/steel. IP67 sealing, ISO 9001 certified. Custom sizes for Siemens, SEW-Eurodrive, Bonfiglioli. Free CAD samples!

Introduction

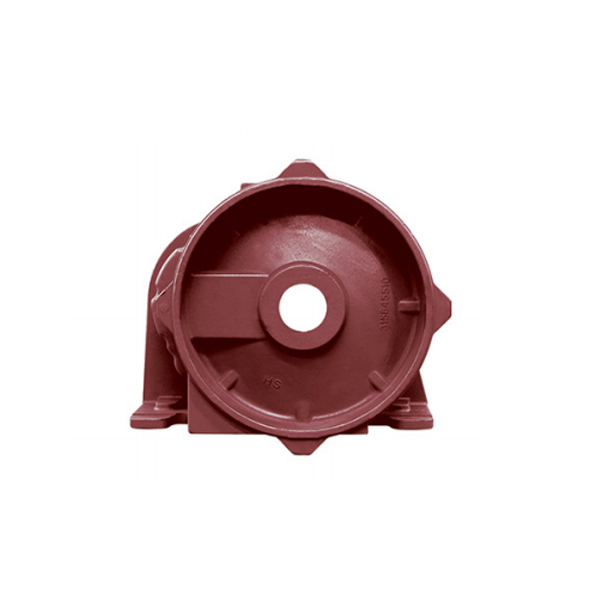

What is a Gearbox End Cap?

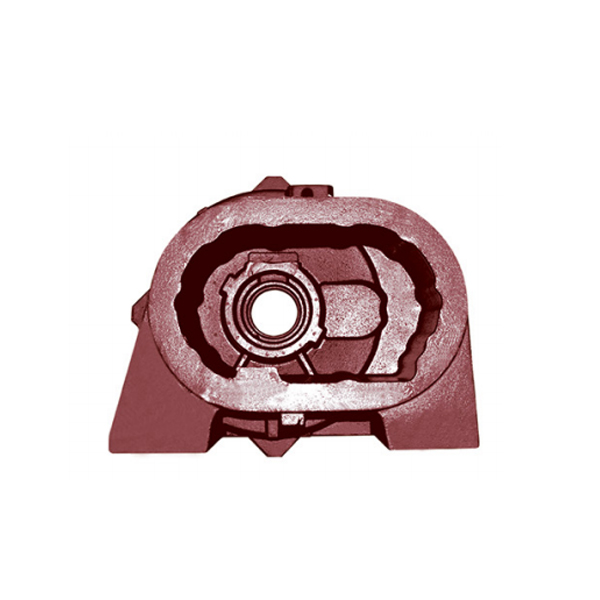

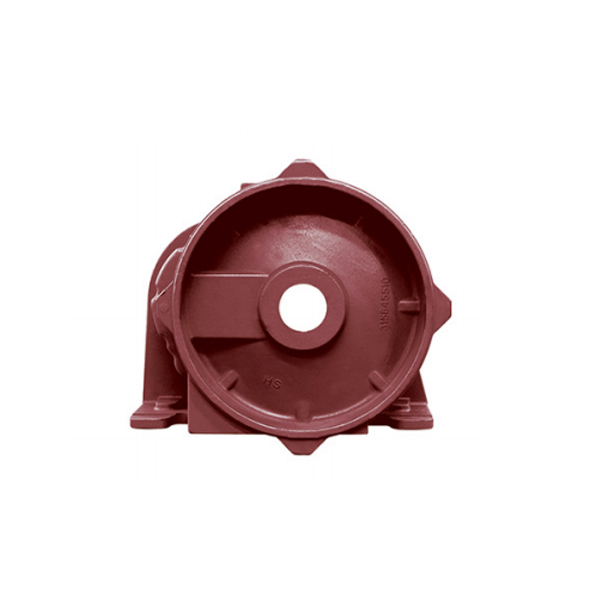

A gearbox end cap (or gearbox end cover) is a critical component sealing the gearbox housing, protecting internal gears and bearings from contaminants while ensuring lubricant retention. Designed to withstand extreme pressures, vibrations, and temperatures, it acts as both a structural support and a barrier against environmental hazards.

Technical Specifications of Our Gearbox End Caps

Material & Manufacturing Process

Materials:

✅ EN-GJL-250 Cast Iron – Ideal for heavy-load industrial gearboxes (mineral processing, conveyor systems).

✅ ASTM A536 Ductile Iron – High tensile strength (≥450 MPa) for wind turbine gearboxes.

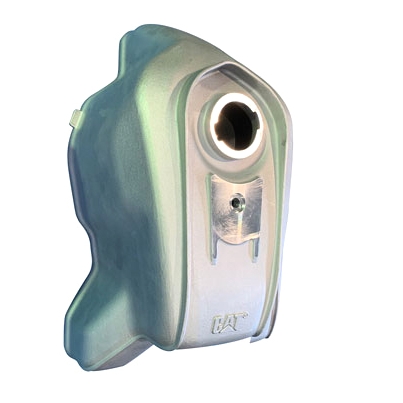

✅ Aluminum ADC12 – Lightweight option for robotics and EV drivetrains.Precision Machining:

5-axis CNC machining achieves IT7 tolerance (bore diameter accuracy: ±0.02mm).

Surface treatments: Phosphating (anti-corrosion), anodizing (aluminum models).

Sealing & Durability

IP67/IP69K Protection – Blocks dust, water jets, and oil mist penetration.

Temperature Range: -40°C to 180°C (certified per ISO 6336 fatigue testing).

Pressure Relief Valve – Optional for high-speed gearboxes to prevent oil leakage.

Key Advantages of Our Gearbox End Caps

1. Extreme Environment Adaptability

Mining & Construction Gearboxes: Resists abrasive dust and shock loads.

Offshore Wind Turbines: Salt spray corrosion protection (ASTM B117 tested).

2. Customization Flexibility

Modify bolt hole patterns (PCD), shaft diameters (Ø50–Ø300mm), and sealing types (O-ring, gasket).

3D CAD Models (STEP/IGES formats) provided within 24 hours.

3. Fast Global Delivery

15-day standard lead time for 2,000+ in-stock models.

Emergency orders shipped via DHL/UPS in 72 hours.

Applications of Gearbox End Caps

✅ Wind Energy: Compatible with Siemens Gamesa 4.X platform & GE Haliade turbines.

✅ Industrial Automation: SEW-Eurodrive R/F series, Nord SK series.

✅ Agricultural Machinery: Reinforced seals to prevent mud ingress.

Certifications & Quality Control

Certifications: ISO 9001:2015, IATF 16949 (automotive), GL Wind (renewables).

Testing Equipment: CMM inspection (accuracy: ±0.005mm), helium leak detection.

Why Choose Us? – Your Trusted Gearbox End Cap Partner with End-to-End Control

✅ 1. Vertical Integration from Smelting to Precision Machining

Low-Sulfur Materials for High-Performance End Caps

In-House Iron Smelting:

230m³ blast furnace produces low-sulfur (≤0.02%) ductile iron, optimized for gearbox end cap fatigue resistance.

Short-process technology feeds molten iron directly to electric furnaces, increasing casting density by 15%.

Full-Process Ownership:

5 casting workshops (lost foam/resin sand/iron mold coating) → 3 machining workshops → Final inspection.

Zero outsourcing risks with 30% faster lead times.

✅ 2. Heavy-Duty Machining for Large Gearbox Components

ISO-Certified Manufacturing for Wind Energy & Mining

Oversized Component Capacity:

CNC vertical lathes handle 30-ton end caps (compatible with 5MW+ wind turbine gearboxes).

Gantry machining centers process flanges up to 6m×3m (for large-diameter end caps).

Precision Bearing Bore Machining:

Guideway grinders ensure end cap flatness ≤0.02mm/m (ISO 2768-mK standard).

✅ 3. Global Validation in Gearbox Applications

Trusted by Industry Leaders

Wind Energy: Supply large end caps to Chinese wind turbine OEMs (1,200+ units/year).

Industrial Gearboxes: Strategic partners include Yuanda Valve (high-pressure end caps) & Jiangte Motor (high-speed sealing covers).

International Compliance: Exports EN-GJS-400-18 certified end caps to German automotive gearbox suppliers.

✅ 4. Sustainable Production with ESG Commitments

Green Manufacturing for Carbon-Neutral Goals

Blast furnace gas power meets 50% plant energy needs → Reduces end cap carbon footprint.

95% sand recycling rate → Minimizes industrial waste.

Full material traceability reports available (from molten iron to finished end caps).

Gearbox End Cap vs. End Cover: What’s the Difference?

While the terms are often used interchangeably, end caps typically refer to compact, bolted-on designs, whereas end covers may include larger flanges or integrated sensor mounts. We provide both solutions – contact u for technical clarification.

FAQs About Gearbox End Caps

Q: Can you replicate end caps from broken samples?

A: Yes! Send us your damaged part – we’ll reverse-engineer and deliver replacements in 10 days.

Q: Do you offer anti-static end caps for explosive environments?

A: Absolutely. Our ATEX-compliant models use conductive nylon seals.

Get Your Gearbox End Cap Quote Today!

Photos

-

Reducer Housing Manufacturer | Custom Cast Iron & Steel Gear Reducer Casings

-

Industrial Gearbox Manufacturer | Custom Cast Iron/Steel Gearboxes for Mining & Wind Energy

-

Electric Motor Castings Manufacturer | Custom Aluminum & Iron Motor Housings

-

High-Quality Taper Bushed Pulleys | SPB/SPA Series | Customizable & Durable

-

Gantry Castings Manufacturer | Custom Steel & Iron Gantry Frame Castings

-

Large Castings Manufacturer | Heavy Iron & Steel Casting Parts Supplier

-

-

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh