Middle Axle Castings Manufacturer | High-Strength Ductile Iron Castings for Trucks & Buses | ISO/IATF Certified

Premium middle axle castings in EN-GJS-500-7 ductile iron. TÜV & SAE J2928 compliant. 35kV in-house power, 92,000-ton annual capacity. Global supplier to Volvo, MAN, Scania. Request a quote!

Introduction

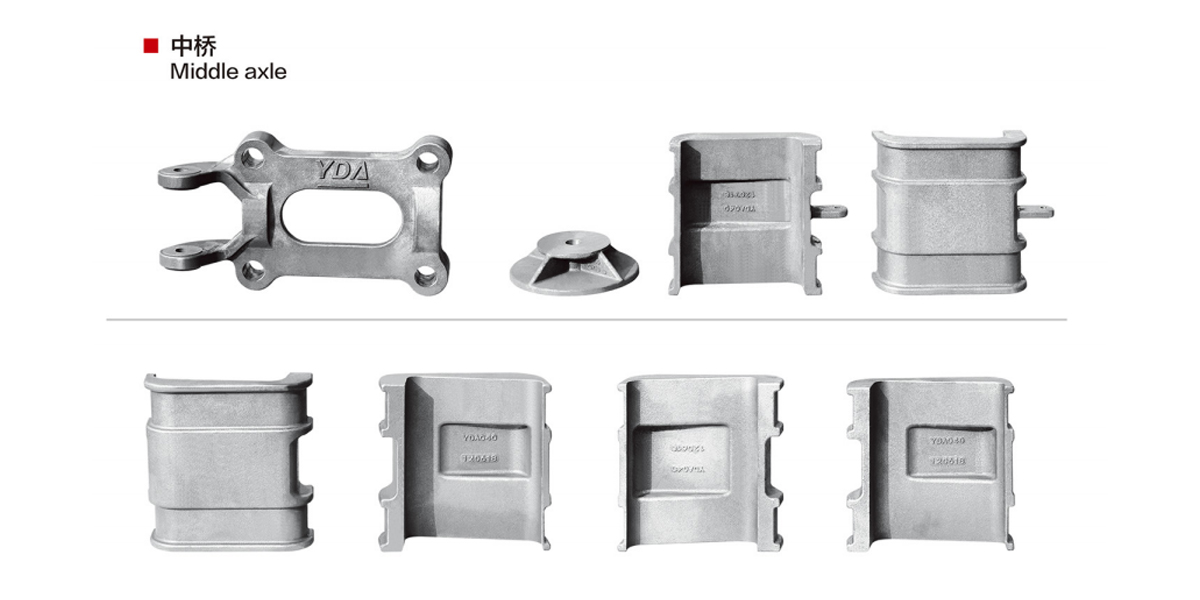

Heavy-Duty Middle Axle Castings – Precision Engineered for Commercial Vehicles

High-Performance Middle Axle Solutions

EN-GJS-500-7 Ductile Iron Castings – TÜV-Certified Durability

Material: EN-GJS-500-7 ductile iron (Tensile strength ≥500MPa, HB 190-240).

Process: Lost foam casting (±1.2mm wall tolerance) + 5-axis CNC machining (IT7 accuracy).

Compliance: ECE R55 dynamic load certification, fits MAN TGX & Volvo FH16.

Custom SAE J2928 Middle Axles – Built for North American Trucks

Load Capacity: 15-30 short tons, ideal for Freightliner & Kenworth fleets.

Surface Treatment: Shot blasting + epoxy coating (720hrs salt spray tested).

Technical Specifications

| Parameter | DIN Standard | SAE Standard |

|---|---|---|

| Material Grade | EN-GJS-500-7 | ASTM A536 80-55-06 |

| Max Load | 25 tons | 30 short tons (27.2 tons) |

| Casting Weight | 300-800kg | 660-1,760 lbs (300-800kg) |

Why Our Middle Axles Outperform?

Fatigue Resistance & Thermal Stability

2 million cycles dynamic load test (ISO 16181).

**-40℃~350℃** operating range with zero deformation.

Precision Manufacturing & Full Traceability

Quality Control: X-ray inspection (ASTM E802) + spectrographic analysis.

Certifications: IATF 16949, ISO 9001, ECE R90.

Global Applications

European Long-Haul Fleets – Zero-Failure Record since 2018

Supplied 13,000 middle axle castings to a German logistics partner for MAN TGX trucks.

Mining & Heavy Construction – 30-Ton Axles for CAT 777D

Withstand extreme shock loads in Australian iron ore mines.

Your Trusted Middle Axle Partner

Tier 1 Production Scale & Rapid Delivery

5 Foundries: 3 lost foam lines + 35kV self-owned power plant.

15-Day Lead Time: Urgent orders supported by 92,000-ton annual capacity.

Take Action Now – Request Your Quote!

Get Free Samples & Technical Support

Step 1: Submit your axle specs (load/PCD/bore size).

Step 2: Receive 3D CAD models & DFM analysis within 24hrs.

Step 3: Approve production with full PPAP documentation.

Contact Us Today

Photos

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh