Precision Car Brake Drums – German DIN & American FMVSS Standards

Premium car brake drums for Volkswagen, Toyota, Ford. TÜV & FMVSS certified. Cast in GGG50 ductile iron & alloy. 35kV in-house power, 92,000-ton capacity. Global OEM supplier.

Introduction

OE Quality Car Brake Drums | DIN/FMVSS Compliant for Sedans, SUVs & EVs | Cast Iron & Alloy Options

Material & Design for Passenger Vehicles

European DIN Brake Drums – TÜV-Certified for VW, BMW, Mercedes

Compatible Models: Volkswagen Golf, BMW 3 Series, Mercedes C-Class.

Material: GGG50 ductile iron (EN 1563), 25% higher thermal crack resistance vs. standard cast iron.

Process: Lost foam casting + CNC machining (±0.1mm bore tolerance).

Compliance: ECE R90 braking performance, compatible with Continental/Bosch systems.

American FMVSS Brake Drums – Ford, Chevrolet, Tesla

Compatible Models: Ford F-150, Chevrolet Silverado, Tesla Cybertruck.

Material: ASTM A159 G10 gray iron, 720+ hours salt spray tested (ASTM B117).

Process: Resin sand casting + zinc plating, friction surface Ra≤6.3μm.

Compliance: FMVSS 135 braking efficiency, fits Brembo® calipers.

Technical Specifications

| Parameter | DIN Brake Drums | FMVSS Brake Drums |

|---|---|---|

| Bore Diameter | 200-300mm | 8-12 inches (203-305mm) |

| Material Hardness | 190-220 HB | 180-200 HB |

| Operating Temperature | -40℃~300℃ | -40℉~572℉ (-40℃~300℃) |

| Surface Treatment | Phosphating + epoxy coating | Zinc plating + electrostatic paint |

Key Applications & Performance

Compact Sedans & Hatchbacks

Pain Point: Brake fade from frequent urban stop-start cycles.

Solution: GGG50 honeycomb cooling ribs reduce heat fade by ≤15% (ECE tested).

Electric SUVs & Pickup Trucks

Pain Point: High braking load due to vehicle weight.

Solution: Reinforced drum walls (12mm→15mm), 20% higher static load capacity.

Why Choose Our Brake Drums?

Tier 1 OEM Manufacturing Expertise

Precision Casting: 5-axis CNC machining for OE-bearing compatibility (FAG/SKF).

Testing: 100% radial runout (≤0.15mm) and noise tests (SAE J2521).

EV & Hybrid Customization

Lightweight Option: Aluminum alloy drums (A356-T6) reduce weight by 30%, ideal for regenerative braking.

Fast Response: 15-day mold development (lost foam process), low-volume trial batches supported.

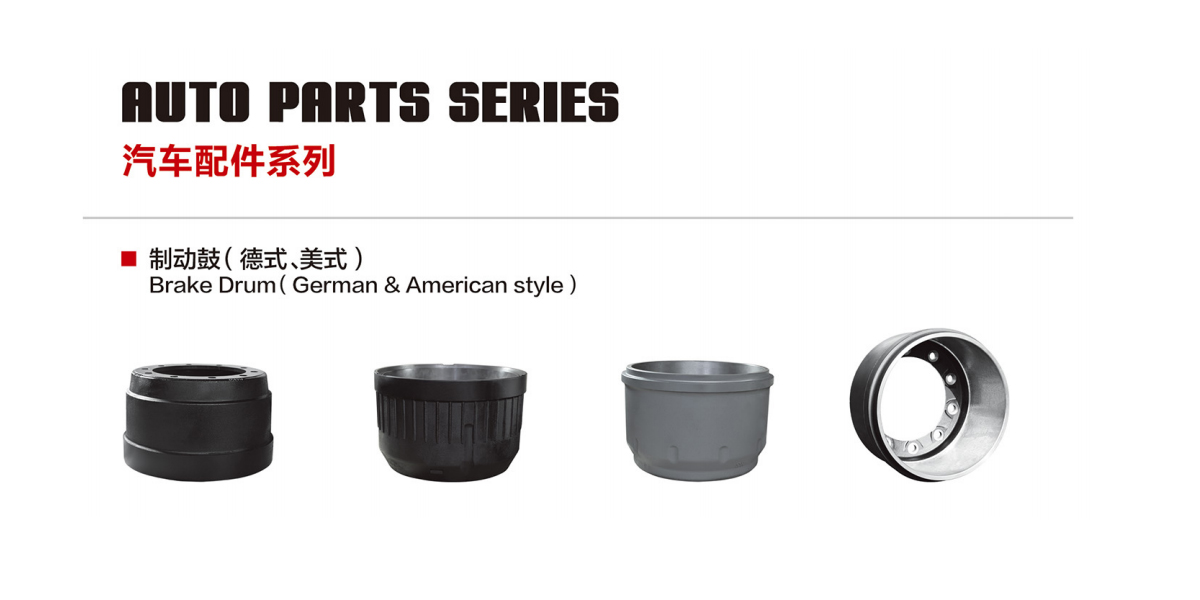

Photos

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh