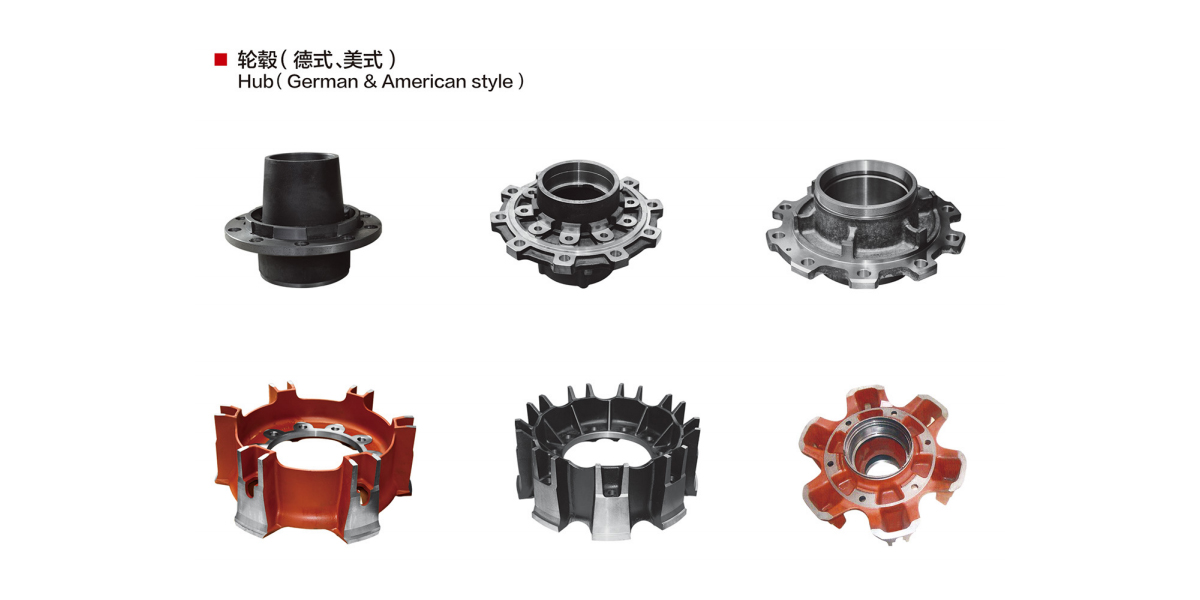

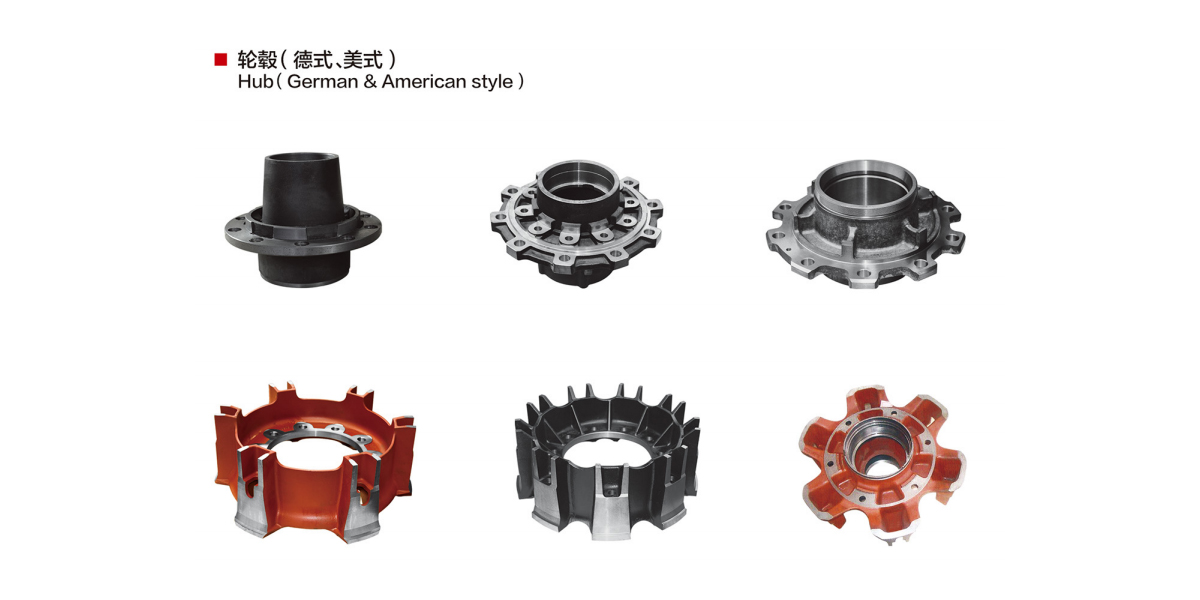

German & American Style Wheel Hubs Manufacturer | DIN/SAE-Compliant for Trucks & Trailers | ISO 9001 Certified

Premium car wheel hubs in aluminum alloy & stamped steel. OEM replacements for Tesla, Toyota, VW. 35kV in-house power, 92,000-ton capacity. CE, TUV, IATF 16949 certified. Global delivery.

Introduction

Precision Automotive Wheel Hubs – OE Quality for Global Passenger Vehicles

Tab 1: German-Style Hubs (DIN Standard)

Target Markets: EU, Middle East, Russia

Compliance:

DIN 7526 (Commercial Vehicle Hub Dimensions)

TÜV-Certified Dynamic Load Testing

Key Processes:

Lost Foam Casting: Single-piece molding, minimizing machining.

Precision Machining: 5-axis CNC machining for bearing seats (±0.05mm tolerance).

Typical Applications:

Mercedes-Benz Actros, MAN TGX Trucks, Krone Trailers.

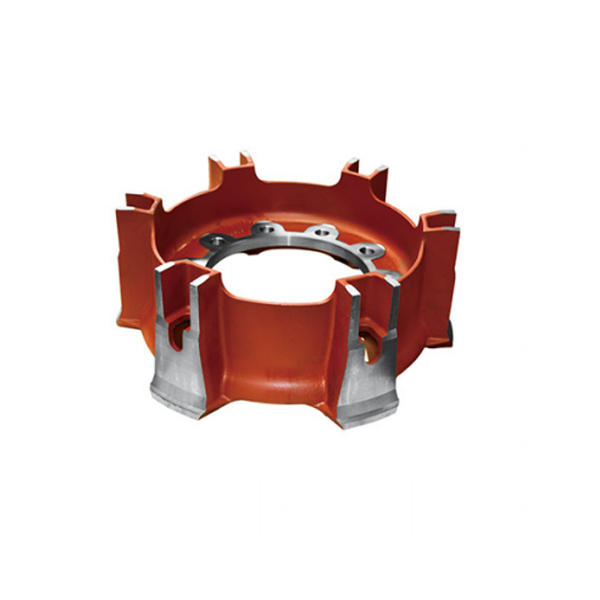

Tab 2: American-Style Hubs (SAE Standard)

Target Markets: North America, South America, Southeast Asia

Compliance:

SAE J2017 (Wheel Hub Bolt Circle Standards)

FMVSS 121 (Brake System Compatibility)

Key Processes:

Resin Sand Casting: High surface finish (Ra≤12.5μm).

Anti-Corrosion Treatment: Phosphating/electrostatic coating, 500-hour salt spray tested.

Typical Applications:

Peterbilt 389, Kenworth T680, Great Dane Trailers.

Technical Excellence in Wheel Hub Manufacturing

ISO 9001 Certified Production Process

Step 1: Smelting in 20-ton electric furnaces with 6,000kW waste heat recovery.

Step 2: 100% X-ray inspection for internal defects (per ASTM E802).

Step 3: 5-axis CNC machining (±0.05mm bore tolerance).

High-Capacity Foundry with 35kV Power Plant

Annual Output: 92,000 tons of castings, including 500,000+ wheel hubs.

Rapid Delivery: 15 days for standard hubs, 30 days for custom designs.

Aftermarket: OEM/ODM support with branded packaging and customs documentation.

Company Strength Module-20+ Years Expertise in Automotive Castings

Why Partner with a Tier 1 Wheel Hub Supplier?

Scale & Stability: 5 foundries, 35kV self-owned power plant, 6,000kW waste heat recovery system.

End-to-End Control: Smelting (300,000-ton annual high-purity iron) to machining (±0.05mm precision).

Global Expertise: Supplying MAN’s OEM partners in Germany and Haas Automation (USA).

Photos

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh