Gantry Castings Manufacturer | Custom Steel & Iron Gantry Frame Castings

Professional gantry castings supplier producing heavy-duty steel and ductile iron castings for cranes, CNC machinery, and port equipment. ISO-certified, competitive pricing. Request a quote!

Introduction

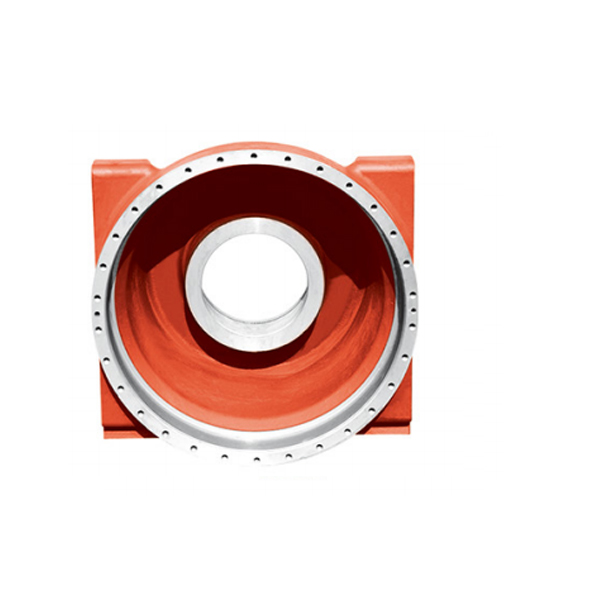

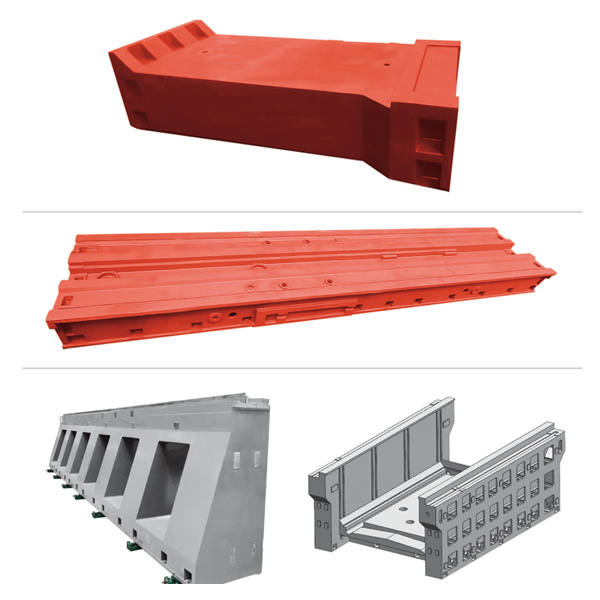

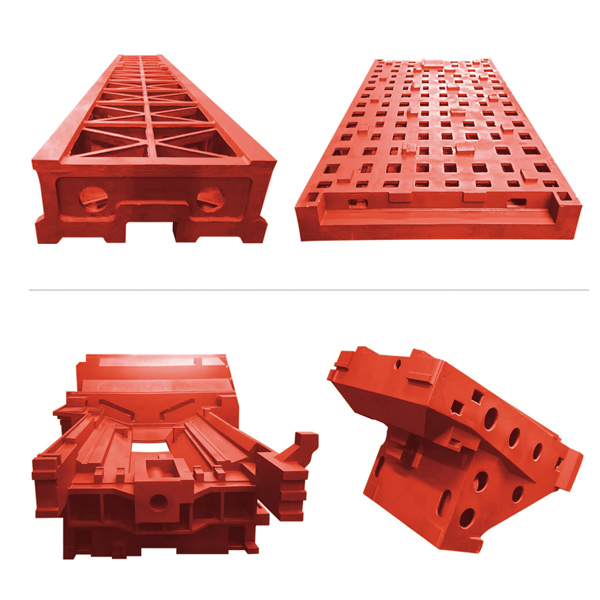

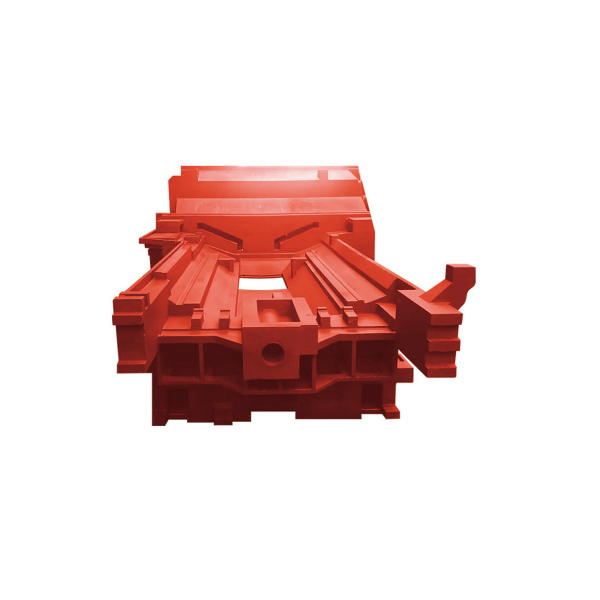

Gantry Castings Manufacturer | Heavy-Duty Steel & Ductile Iron Frame Castings

Our gantry castings are engineered to support high-load applications, such as overhead crane systems and CNC gantry mills. Using resin sand casting technology, we provide custom gantry

frame castings in materials like EN-GJS-500-7 ductile iron and ASTM A27 steel, with weights up to 15 tons.

| Category | Specifications |

| Material | Ductile Iron (EN-GJS-500-7), Carbon Steel (ASTM A27) |

| Weight Range | 1,000 kg – 30,000 kg |

| Max. Dimensions | 10m (Length) × 3m (Width) × 2m (Height) |

| Tolerance | ±1.2 mm/m (As per ISO 8062) |

| Surface Finish | Machined, Painted, or Galvanized |

| Certification | ISO 9001, CE, DNV (Marine Grade Options) |

Our gantry frame castings are manufactured using resin sand casting and lost foam casting technologies, ensuring dimensional accuracy for seamless integration with mechanical systems. All castings undergo **ultrasonic testing (UT) and magnetic particle inspection (MT)** to eliminate internal defects.

Our ductile iron gantry castings (Tensile Strength: 500 MPa) withstand dynamic loads up to 150 tons, ideal for port gantry cranes and heavy machinery.

Transportation modes:Including sea transportation, railway transportation, and road transportation.

Minimum order quantity:Comprehensive evaluation based on actual orders.

Qualification certification: Complete qualifications to ensure reliable quality.

Sales countries:We have provided products to users regions including Asia, Southeast Asia, Europe, North America, and Africa, serving countries such as the United States, Japan, South Korea, France, Germany, Thailand, Vietnam, the United Arab Emirates, and Saudi Arabia. Looking ahead, we eagerly anticipate cooperating with more global buyers.

FAQ

Q1:How do you ensure your product quality?

A: We strictly adhere to international standards and industry norms for production and quality control. All products undergo rigorous quality testing to ensure they meet customers' requirements and expectations. Additionally, we provide a comprehensive quality assurance system and after-sales service.

Q2:What are your main casting products?

A:Our castings are widely used in various fields such as automobiles, engineering machinery, mining machinery, agricultural machinery, machine tools, piping, renewable energy, and municipal infrastructure. Specific components include heavy-duty truck chassis parts like integral crossbeams, U-bolt seats, leaf spring seats, support seats, balance shaft housings, steering gear housings, and engine brackets; engine parts such as flywheels and flywheel housings; axle parts including base plates, shoe brakes, hubs, brake hubs, calipers, brackets, differential housings, and wheel hubs; wind power components like motor bases and lower engine blocks; and agricultural machinery parts such as counterweights.

Q3:What are the grades of castings you produce?

A:Our castings primarily include gray iron and ductile iron: Gray iron grades: HT100, HT150, HT200, HT250, HT280, HT300, HT350, HT400; Ductile iron grades: QT400, QT450, QT500, QT600, QT700, QT800, etc.

Q4:Do you have surface treatment capabilities?

A:Yes, we have professional painting lines and spray painting rooms that can meet various primer and topcoat painting requirements.

Q5:What casting production processes do you have?

A:We currently offer sand casting, investment casting (also known as lost-wax casting), die casting, pressure casting, centrifugal casting, full mold casting (also known as lost foam casting), and V-process casting (also known as vacuum casting).

Q6:What are your advantages?

A:We have our own supply chain for pig iron and ferroalloys, providing us with material cost advantages and material security.

We have developed our own product lines and integrated resources from thousands of high-quality casting suppliers in China, enjoying a good reputation in our collaborations.

We can meet the casting needs of 99% of our customers.

Q7:What after-sales services do you provide?

A:Tiegu provides comprehensive after-sales services including product consultation, technical support, repair, and replacement. If you encounter any issues or need assistance during use, please feel free to contact our customer service team. We will sincerely provide you with excellent service and support.

Q8:Do you have the capability for customized processing?

A: We have a machining workshop equipped with various large, medium, and small numerical control gantry machines, machining centers, and other professional equipment. With years of experience in casting engineering, we can provide comprehensive customized services.

Q9:How can I establish a partnership with you?

A: You can fill out an online form and leave your information, or directly contact our team.

Photos

-

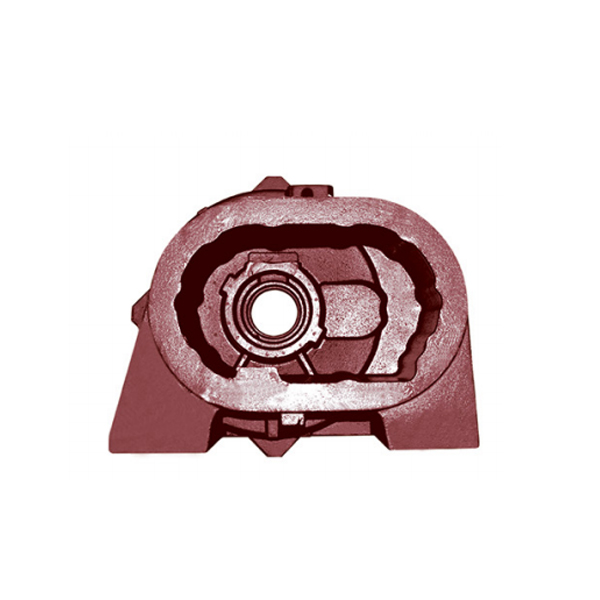

Reducer Housing Manufacturer | Custom Cast Iron & Steel Gear Reducer Casings

-

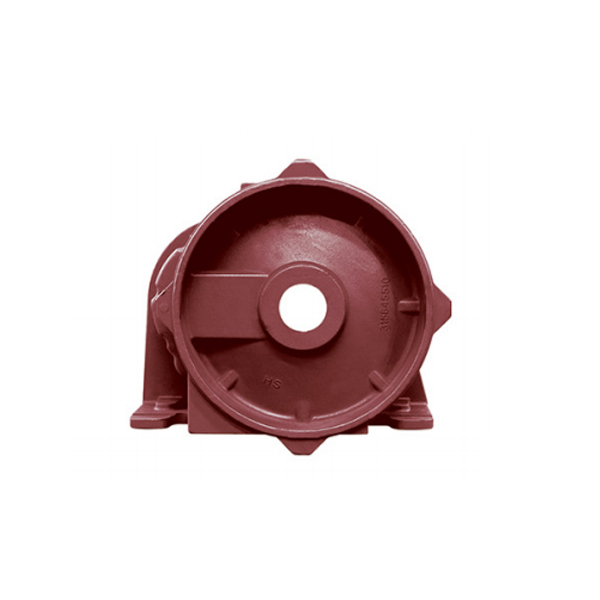

Industrial Gearbox Manufacturer | Custom Cast Iron/Steel Gearboxes for Mining & Wind Energy

-

High-Performance Gearbox End Caps | Industrial-Grade Sealing Solutions for Gearboxes

-

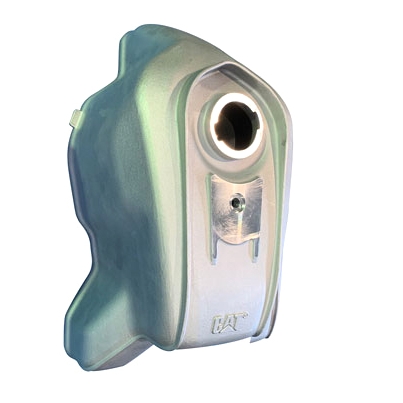

Electric Motor Castings Manufacturer | Custom Aluminum & Iron Motor Housings

-

High-Quality Taper Bushed Pulleys | SPB/SPA Series | Customizable & Durable

-

Large Castings Manufacturer | Heavy Iron & Steel Casting Parts Supplier

-

-

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh