What is Water Glass Investment Casting?

2025-01-15 15:36:19 hits:0

Water glass investment casting, a modern precision casting technique, is widely used in industries such as aerospace, automotive, and machinery for manufacturing high-precision, complex-shaped castings. It utilizes water glass (sodium silicate solution) as a binder and a series of special processes to cast fine metal parts. So, how does water glass investment casting work? What are its advantages? Let's explore it further.

1. Basic Principle of Water Glass Investment Casting

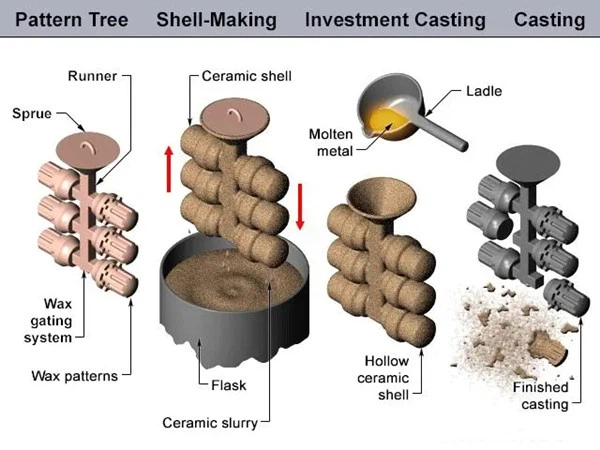

Water glass investment casting is a special form of the "lost wax casting" method. The basic process is similar to traditional lost wax casting, but instead of using traditional binders, it uses water glass to make the mold. The basic process flow includes the following steps:

1.Making the Model: First, a model of the casting is made using 3D printing or other methods, typically with wax or other meltable materials.

2.Coating with Water Glass Slurry: The model is immersed in a water glass slurry, which typically contains silica sand or other fine particles. The model is repeatedly coated and dried, gradually forming a sturdy shell.

3.Burnout and Wax Removal: After the shell has dried and solidified, it is placed in a high-temperature furnace for wax removal. The heat causes the wax model to melt and drain out, leaving a cavity, which is the shape of the casting.

4.Casting: After the wax is removed, the shell is heated to a certain temperature, and molten metal is poured into the mold cavity. Once it cools, it forms the casting.

5.Shell Removal and Cleaning: After the casting cools, the water glass shell is removed, and the casting undergoes post-processing and cleaning to meet the required specifications.

2. Advantages of Water Glass Investment Casting

Compared to traditional casting methods, water glass investment casting offers several distinct advantages:

1.High Precision and Complex Shapes

Water glass investment casting can produce very fine and precise castings, making it ideal for complex-shaped components. The high precision of the mold allows for the production of intricate structures that are difficult to achieve with traditional casting methods.2.Suitable for High-Temperature Alloys

This casting process has unique advantages when used for high-temperature alloys. Since the water glass mold has a relatively high resistance to high temperatures, it is ideal for pouring metals like nickel alloys, cobalt alloys, and other high-temperature materials.3.Smooth Surface Finish

The molds produced by water glass investment casting have a smooth surface, resulting in castings with high-quality surface finishes. This reduces the need for complex post-processing, saving time and costs.4.Ideal for Small-Batch Production

This technique is particularly well-suited for small-batch, high-precision production requirements. It is widely used in industries like aerospace, medical equipment, and high-end mechanical parts.5.Reduced Machining

Due to the high precision of the castings, the amount of post-machining is reduced, improving production efficiency.3. Applications of Water Glass Investment Casting

Due to its unique advantages, water glass investment casting is widely used in several industries, especially in sectors where casting quality is critical. The main applications include:

1.Aerospace

In the aerospace industry, water glass investment casting is commonly used to manufacture high-precision parts like engine blades and turbine blades. These parts require high strength, high-temperature resistance, and extreme precision.2.Automotive Industry

In the automotive industry, water glass investment casting is used to make engine components, precision gears, and transmission housings, meeting the demand for high performance and durability.3.Mold Manufacturing

Water glass investment casting is also widely used in the production of precision molds, especially when complex geometries and high precision are needed.4.Medical Equipment

The precision parts used in medical devices also benefit from water glass investment casting, ensuring the required accuracy and quality of the components.

4. Conclusion

Water glass investment casting, as a modern precision casting technology, has been widely applied in many high-end manufacturing fields due to its ability to produce high-precision, complex-shaped components. As technology continues to evolve, this casting technique will likely demonstrate its unique advantages in even more industries. If you need to manufacture complex, high-precision castings, water glass investment casting is undoubtedly an excellent choice to consider.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh