Definition, Classification Standards, and Applications of High-Purity Pig Iron

2025-01-15 10:33:06 hits:0

1. Definition:

High-purity pig iron refers to pig iron with extremely low impurity content, mainly elements like sulfur, phosphorus, manganese, and silicon. It is typically used in the production of specialty steel or precision castings. It is produced through specific smelting processes to achieve high metal purity and minimal harmful elements.

2. Classification Standards:

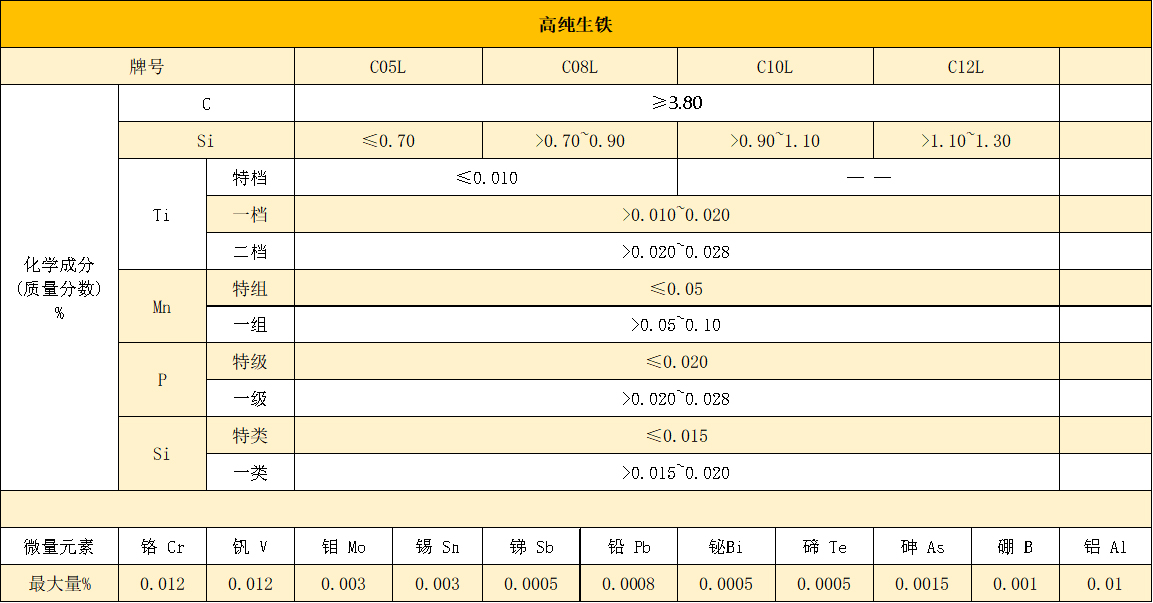

In China, high-purity pig iron is usually classified based on different standards. Common classification criteria include:

- Chemical Composition: The sulfur, phosphorus, manganese, silicon, and other impurity elements in high-purity pig iron are tightly controlled. The impurity content is usually lower than that in standard pig iron.

- Sulfur content: ≤ 0.02%

- Phosphorus content: ≤ 0.02%

- Manganese content: ≤ 0.5%

- Silicon content: ≤ 1.0%

The specific values may vary based on specific requirements. Standards like GB/T 3085-2002 ("Pig Iron") from China can provide more detailed guidelines.

- Specific Applications: High-purity pig iron is further subdivided according to its use, such as high-purity casting pig iron or high-purity steelmaking material.

3. Main Uses:

High-purity pig iron, due to its excellent chemical composition and low impurity content, is widely used in the following areas:

- High-end Steel Production: Due to its low impurity content, high-purity pig iron is used to produce high-strength, corrosion-resistant, and high-precision steels, such as stainless steel, tool steels, and specialty alloy steels.

- Casting Industry: High-purity pig iron is used to produce high-quality castings, especially for those requiring high temperature resistance, corrosion resistance, or precision, such as in automotive or aerospace components.

- Electrical Steel Production: High-purity pig iron can be used to make electrical steel (especially silicon steel), where low impurity content is critical to avoid performance degradation due to impurities.

- Special Alloys: It is also a key material for producing certain special alloys, such as high-performance aluminum alloys or titanium alloys.

- Magnetic Materials: Due to its low impurity content, high-purity pig iron contributes to the stability and performance of certain magnetic materials.

4. Production Methods:

High-purity pig iron is typically produced using the following methods:

- Blast Furnace Smelting: Blast furnace smelting is the main method for producing pig iron. However, for high-purity pig iron, controlled smelting processes are needed to strictly manage the composition of raw materials and reduce impurity content.

- Electric Furnace Smelting: Electric furnace smelting allows better control of temperature and reaction atmosphere, and through precise control, high-purity pig iron can be produced.

- Vacuum Smelting: This method helps to remove harmful gases and impurities from the molten iron, improving purity.

- Refining Treatment: Additional refining methods (such as oxygen top-blowing or out-of-furnace refining) are often used during the smelting process to further reduce impurities.

5. Summary:

High-purity pig iron is an important basic material with low impurities, making it essential for producing high-end steels, specialty alloys, electrical steels, and casting materials. As modern industries demand higher performance materials, the demand for high-purity pig iron is steadily increasing, especially in high-precision fields like aerospace, electronics, and energy.

Tiegu supplies high-quality high-purity pig iron to global users. Friends in need can click to view

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh