Comparison of Carbon Steel Pipes and Ductile Iron Pipes in Water Supply and Drainage Systems

2025-01-14 22:03:01 hits:0

1. Applications of Carbon Steel Pipes in Water Supply and Drainage

Carbon steel pipes are pipes made from carbon steel material, with certain strength and pressure resistance properties. They are widely used in water supply and drainage systems.

Applications:

- Water Supply Networks: Carbon steel pipes are commonly used in municipal water supply systems, industrial water supply networks, and certain rural water pipelines, especially in situations where high water pressure is required.

- Drainage Networks: They can also be used in drainage systems, particularly in industrial wastewater discharge.

- Hot Water Systems: Due to the good heat resistance of carbon steel pipes, they are suitable for hot water pipelines.

Characteristics:

- Good Pressure Resistance: Carbon steel pipes can withstand high water pressure, making them suitable for large-diameter water supply pipelines.

- High Mechanical Strength: They have high strength, making them suitable for situations that require resistance to external mechanical forces.

- Relatively Low Cost: Compared to other types of pipes (such as stainless steel or ductile iron pipes), carbon steel pipes are cost-effective and economical.

2. Applications of Ductile Iron Pipes in Water Supply and Drainage

Ductile iron pipes are pipes characterized by spheroidal graphite in their material, which gives them high strength and corrosion resistance. They are widely used in municipal water supply and drainage systems.

Applications:

- Urban Water Supply Systems: Ductile iron pipes are widely used in urban water supply networks due to their corrosion resistance, pressure resistance, and abrasion resistance, especially in underground pipelines.

- Drainage Systems: They are used in drainage and sewage pipes, particularly in corrosive environments.

- Pressure Pipelines: Suitable for high-pressure pipelines or large-diameter pipelines.

Characteristics:

- Excellent Corrosion Resistance: Ductile iron pipes are more resistant to corrosion compared to carbon steel pipes, making them suitable for environments with highly corrosive soil and water.

- Good Pressure Resistance: Ductile iron pipes can withstand greater external and internal pressures, making them suitable for long-distance, large-diameter pipelines.

- High Toughness: They have high impact resistance and toughness, which helps to prevent damage from external forces.

- Heavy Weight: Ductile iron pipes are heavier than carbon steel pipes, leading to higher transportation and installation costs.

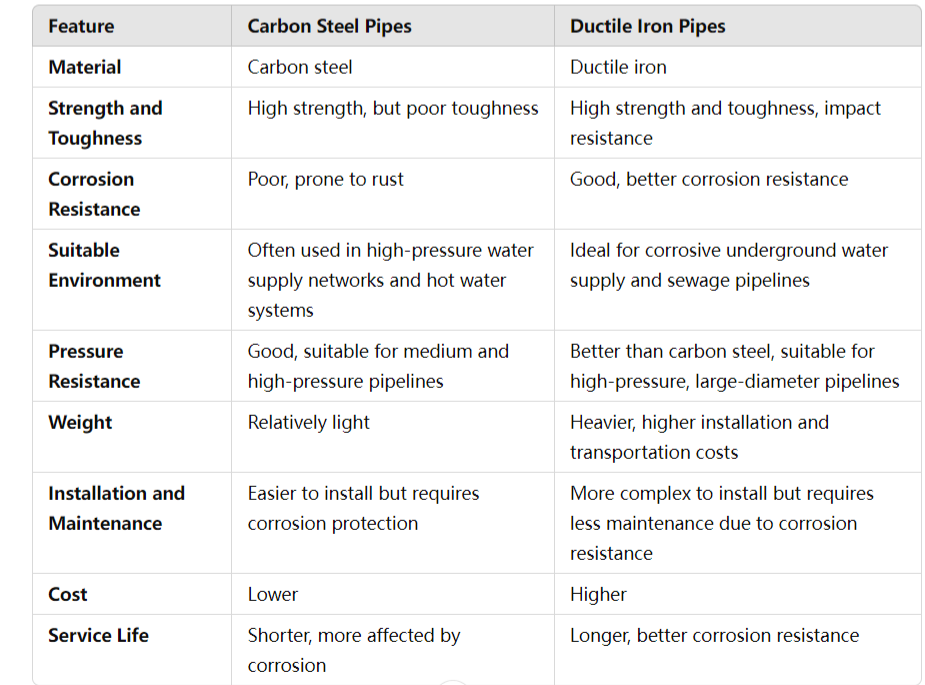

3. Differences Between Carbon Steel Pipes and Ductile Iron Pipes

4. Summary

- Carbon Steel Pipes: Suitable for situations where economic factors are more important, pressure is moderate, or where external mechanical forces are required. They are often used in pressure pipelines, industrial pipelines, and water supply systems.

- Ductile Iron Pipes: More suitable for long-term use, especially in corrosive environments such as urban water supply and sewage networks. Due to their superior corrosion resistance and toughness, ductile iron pipes typically have a longer service life, although they are heavier and more expensive.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh