How to Improve the Strength of Hot Box Sand Cores?

2025-01-08 09:46:04 hits:0

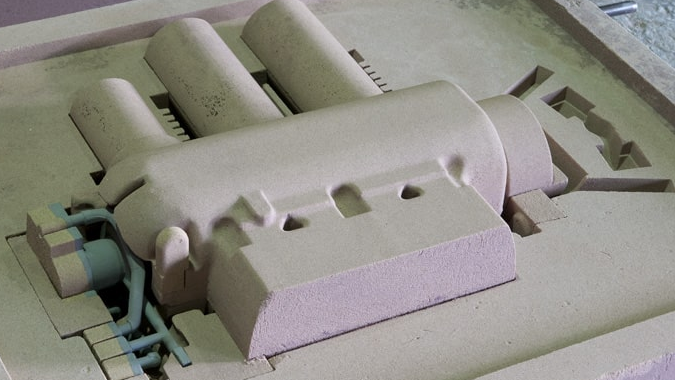

In the casting production process, hot box sand cores are crucial for supporting the shape of the casting and ensuring the precision of the final product. The strength of the sand core directly affects the casting quality, production efficiency, and the accuracy of the final product. Sand cores are required to maintain sufficient support and durability at high temperatures to prevent breakage or deformation during the casting process. Improving the strength of the sand core is key to ensuring casting quality and production stability. This article will explore the factors that influence the strength of hot box sand cores and propose effective improvement measures.

I. Factors Affecting the Strength of Hot Box Sand Cores

1.Selection of Sand Core Materials

- Grain Size Distribution: If the sand particles are too coarse or too fine, it will affect the strength of the sand core. Coarse sand increases the porosity of the core, reducing its strength, while very fine sand may make the core overly compact, affecting its permeability.

- Grain Shape: The shape of the sand particles affects the core's compressibility and strength. Uniform and regular-shaped sand particles are better able to pack together, thereby improving the core's strength.

2.Selection of Core Binders

- Water Glass: Often used in high-temperature casting processes due to its strong heat resistance, but it may have lower hardness at lower temperatures.

- Organic Binders: Typically provide better strength and bonding properties, but they may soften or deform at high temperatures.

3.Sand Core Molding Process

The molding process used for sand cores plays a significant role in their final strength. Common molding methods include manual molding, mechanical molding, and injection molding.- Manual Molding: Simple to operate but has low production efficiency and inconsistent core quality, which can lead to unstable strength.

- Mechanical Molding: Mechanical molding can effectively increase the strength and precision of sand cores, making it suitable for mass production.

- Injection Molding: High-precision molds can produce fine core structures, usually improving uniformity and strength.

4.Drying and Curing Treatment of Sand Cores

- Drying Temperature: High drying temperatures accelerate the curing of the binder but may cause surface cracking if the temperature is too high.

- Curing Time: If the curing time is too short, the core may not fully harden, reducing its strength. Conversely, curing for too long can extend production cycles and affect efficiency.

5.Permeability of Sand Cores

During the casting process, sand cores must withstand the pressure and high temperatures of molten metal. If the core lacks sufficient permeability, casting defects such as gas pockets and cracks may occur.- Permeability: The permeability of a sand core is typically related to its porosity and pore structure. Proper porosity and uniform pore distribution can improve the core's permeability, reducing gas accumulation during casting.

II. Effective Methods to Improve the Strength of Hot Box Sand Cores

1.Optimize Sand Material Selection and Proportions

Choosing the right sand material and optimizing the sand mix is the foundation for improving core strength. Select sand with appropriate particle size, uniformity, and high purity to improve the core's compactness and strength while reducing porosity.2.Use Efficient Binders

Select the appropriate binder and optimize the binder content and mix ratio. The binder helps tightly bond the sand particles while ensuring the core's hardness and strength. Choose binders that are suitable for the temperature range and casting process to ensure the core does not soften or deform at high temperatures.3.Control Molding Process Parameters

Whether using manual, mechanical, or injection molding, it is crucial to strictly control the process parameters to ensure uniform density and improve the core's strength and precision. Mechanized and automated molding increases production efficiency and consistency while reducing the influence of human error on quality.4.Improve Drying and Curing Processes

During the drying process, carefully control temperature, humidity, and time to ensure the sand core hardens fully. Both high and low temperatures can negatively impact the core's strength, so it is important to follow the optimal drying procedure based on the material used and regularly check the drying results.5.Enhance the Permeability of Sand Cores

Improve the permeability of sand cores by optimizing their porosity and pore distribution. By controlling the sand grain size and adding special permeability-enhancing additives, it is possible to reduce gas accumulation during the casting process and avoid defects in the final casting.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh