How to Select Appropriate Sand Casting Factories?

2025-01-07 10:05:15 hits:0

When you decide to customize and purchase a batch of castings using the sand casting process, finding a suitable sand casting factory is of crucial importance. This is directly related to the quality, delivery cycle, and cost of the sand casting products. The following are some key steps to help you screen out the ideal partner.

I. Clarify Your Own Requirements

Before searching for a sand cast foundry, it is essential to meticulously sort out your requirements for the castings. This includes the material types of the castings, such as cast iron, cast steel, or aluminum alloy, etc. Different materials have different process key points during casting; precise dimensional specifications, with the tolerance range strictly defined, as minor deviations may affect subsequent product assembly; the expected production volume, as small-batch trial production and large-scale production have different capacity adaptabilities for the sand casting foundry; and special performance requirements, such as the strength, toughness, and corrosion resistance of the castings. These will determine the subsequent processes like heat treatment required.

II. Preliminary Research

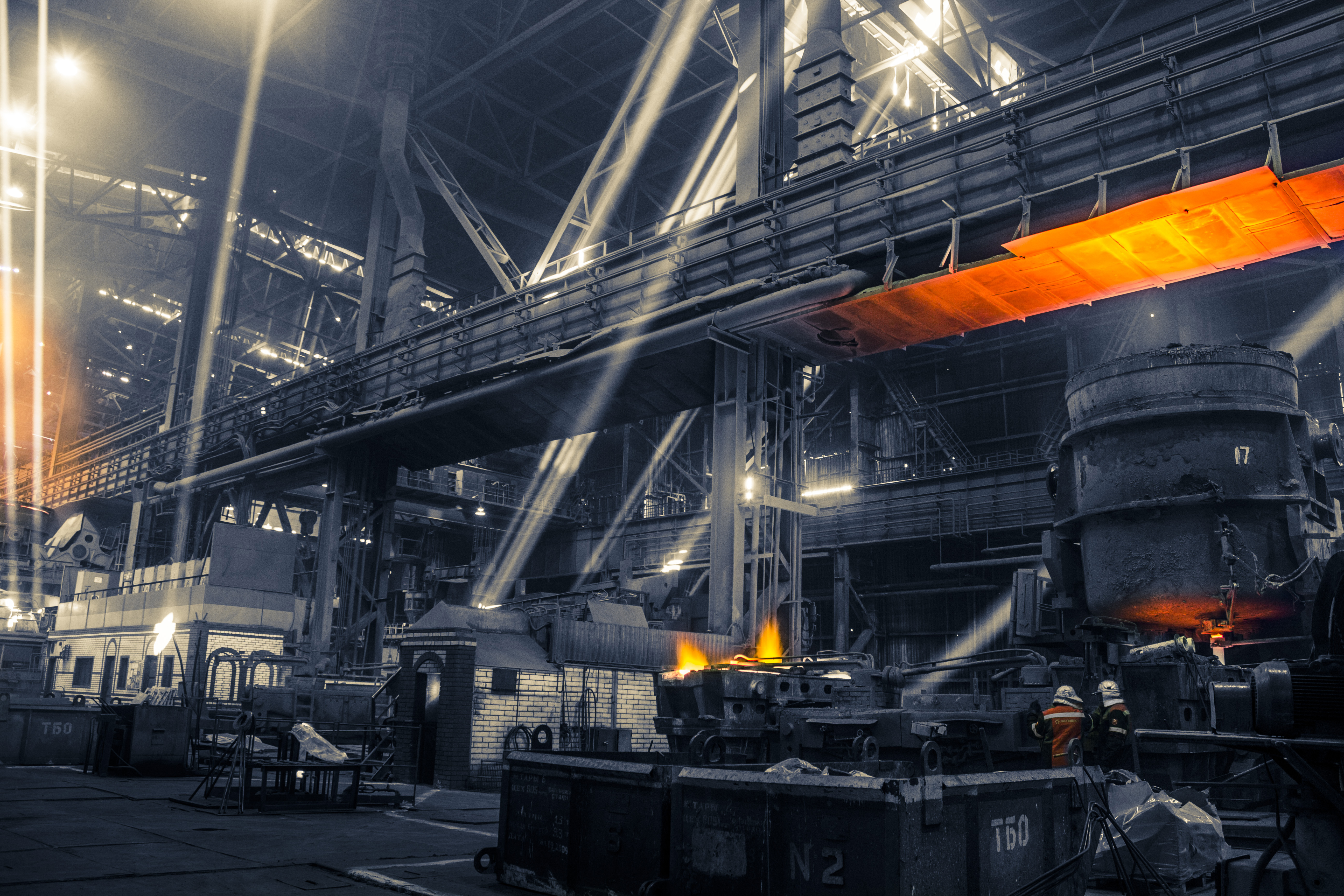

- Utilize Online Resources: Use search engines to look for sand casting manufacturers/suppliers/foundries/factories. Browse their official websites to understand basic enterprise information, such as the years of establishment, sand casting foundries scale, and main product types. Check the displayed cases to see if there are any successful projects similar to your requirements. Make a preliminary judgment of the technological level from the pictures and introductions.

- Industry Platforms and Forums: Participate in professional forums and industry exchange platforms related to casting. Post your requirements or search existing discussion threads in them. You can obtain word-of-mouth recommendations from practitioners, feedback on the actual situations of some factories, and also learn about the advantages of casting industry clusters in specific regions. Due to long-term industrial accumulation in some areas, the technology is mature and the supporting facilities are complete, and local factories may be more competitive.

III. Qualification Verification

- Production Qualifications: Ensure that the sand casting factoryry has legal and compliant production and operation licenses. This is the basic guarantee to avoid legal risks in cooperation. For the production of castings used in specific fields such as aerospace and automotive key components, the sand casting foundries also needs to have corresponding industry quality system certifications, such as ISO 9001, IATF 16949, etc. These certifications indicate that its production process follows strict standards.

- Environmental Protection Qualifications: Sand casting involves environmental issues. The sand casting factory should hold a sewage discharge permit and have complete environmental protection treatment facilities, such as dust collection and wastewater treatment systems, to prevent production stoppages due to environmental violations from affecting your order delivery. It is also a manifestation of corporate social responsibility.

IV. On-site Inspection

- Production Equipment: On-site inspection of whether the sand processing equipment is advanced and efficient. Old and damaged equipment is likely to cause unstable quality of molding sand, affecting the surface quality of castings; the furnace capacity and temperature control accuracy should meet the requirements of your production volume and material melting. High-precision temperature control is crucial for ensuring the uniform composition of materials; the automation degree of the molding production line. High automation can improve efficiency and reduce human errors. If your order volume is large, more attention should be paid to its capacity redundancy.

- Technological Capabilities: Observe the proficiency of workers' operations. Skilled workers can accurately execute process details and reduce the scrap rate; understand the sand casting suppliers's mold design and manufacturing capabilities, and whether it can quickly respond to mold modifications, which is of great significance for new product development and product optimization; inquire about its quality inspection methods, such as whether there are advanced flaw detection equipment and spectrometers to ensure quality control throughout the process from raw materials to finished sand casting products.

- Storage and Logistics: Check the raw material warehouse to understand the types and quantities of its raw material reserves. Adequate reserves ensure production continuity and avoid delays due to material shortages; the finished product storage conditions should be appropriate to prevent castings from getting damp and rusty; understand its logistics distribution methods and which logistics companies it cooperates with, and whether it can meet your expectations for delivery timeliness and transportation safety.

V. Cost Evaluation

- Quotation Details: Require the factory to provide a detailed quotation covering raw material costs, processing fees, mold costs (if any), surface treatment costs, packaging and transportation costs, etc., to prevent hidden costs and compare the rationality of charges in each link among different factories.

- Payment Terms: Negotiate the payment cycle. Common models include advance payment, progress payment, and final payment. Balance the capital pressures of both parties and avoid unreasonable advance payment requirements. At the same time, it also gives the factory capital guarantee for continuous production. For long-term cooperation, more flexible and mutually beneficial payment strategies can be explored.

VI. Customer Service and After-sales

- Communication Response: From the initial contact, pay attention to the timeliness and professionalism of the sand casting manufacturers's business personnel in communication. Whether they can patiently answer questions and quickly handle problems is extremely crucial for order follow-up and problem coordination in subsequent cooperation.

- After-sales Guarantee: Understand its policies for handling defective sand casting products, whether there are recall and repair mechanisms, and how long the after-sales response time is. High-quality after-sales service can reduce your quality risk costs and ensure worry-free procurement.

Through the above rigorous steps and comprehensive consideration of various factors, you will be more confident in screening out high-quality sand casting factories that can meet your sand casting needs, and start a smooth procurement cooperation journey, laying a solid foundation for the successful launch of your products.

Tiegu is a casting supplier from China, with rich casting processes including sand casting, precision casting, etc. If you have casting procurement and customization needs, please contact me.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh