Differences in the Manufacturing and Design of Electric Vehicles vs. Traditional Cars

2024-12-27 16:24:31 hits:0

With the growing global focus on environmental protection and sustainable development, electric vehicles (EVs) have emerged as the future of the automotive industry. Compared to traditional internal combustion engine (ICE) cars, electric vehicles differ significantly in design, manufacturing, power systems, and driving experience. These differences not only impact technological innovation in the automotive industry but also drive the transformation of the entire sector. This article will explore the differences in the manufacturing and design of electric vehicles and traditional cars, and analyze the technological trends and industry changes behind these differences.

1. Key Differences Between Electric and Traditional Cars

1.1Power System

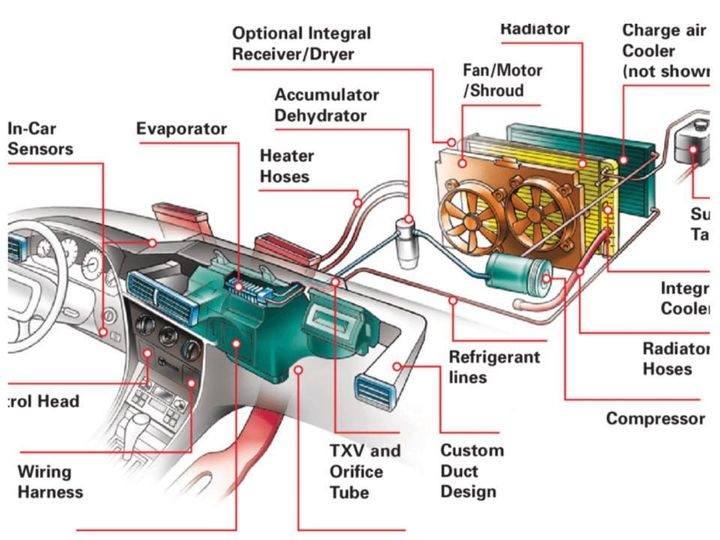

- Traditional Cars: Internal combustion engine cars generate power by burning gasoline or diesel. The engine generates mechanical power, which is transmitted to the wheels through a transmission. This method has high energy density but is harmful to the environment and relies on non-renewable fossil fuels.

- Electric Vehicles: EVs are powered by electric motors, which convert electrical energy stored in batteries into mechanical energy to drive the vehicle. The electric motor’s operation is quite different from an internal combustion engine. EVs offer smoother power delivery, quicker torque response, and better acceleration performance compared to traditional cars.

1.2Energy System

- Traditional Cars: Traditional cars rely on fossil fuels such as gasoline and diesel, which have high energy density but are non-renewable. Burning these fuels emits harmful gases, which contribute to air pollution and climate change.

- Electric Vehicles: EVs use rechargeable batteries, most commonly lithium-ion batteries, to store and supply energy. EVs do not emit harmful pollutants during operation, and their batteries can be charged using renewable energy sources, offering a more sustainable energy model.

2. Differences in Manufacturing

2.1Number of Components

EVs require fewer components compared to traditional cars. Traditional vehicles feature complex powertrains, including the engine, transmission, exhaust system, and more, whereas electric vehicles use an electric motor, controller, and battery pack. This simplified design leads to a more efficient manufacturing process, fewer points of failure, and improved vehicle reliability.2.2Manufacturing Process

The production process for electric vehicles differs from that of traditional cars. Because electric motors are simpler and don’t require the high-temperature, high-pressure environment of internal combustion engines, EV manufacturing focuses more on battery assembly and the installation of electric drivetrains. Additionally, battery production is a critical part of EV manufacturing, with strict requirements for precision and safety.2.3Supply Chain Structure

The supply chain for electric vehicles differs significantly from that of traditional vehicles. Traditional cars depend on suppliers for components such as engines, transmissions, and exhaust systems. In contrast, EVs are more reliant on suppliers of batteries, electronic components, chips, and software. Battery production, in particular, is a high-tech field, with most high-performance batteries sourced from specialized manufacturers. As the market matures, more automakers are vertically integrating the supply chain and starting to develop their own batteries.3. Differences in Design

3.1Exterior Design

Electric vehicles have more flexibility in their exterior design due to the compactness of the electric motor. Without a large engine compartment, the front end of the vehicle can be restructured, allowing for sleeker, more aerodynamic designs that reduce air resistance. This not only improves the vehicle’s range but also enhances its modern aesthetic appeal.3.2Interior Space Layout

Because electric vehicles don’t need to accommodate an internal combustion engine or a complex transmission system, more interior space is available. The battery pack is typically located in the vehicle's floor, freeing up room for passengers and luggage. Additionally, this battery placement lowers the vehicle’s center of gravity, improving stability and handling.3.3Aerodynamics

EVs require a greater emphasis on aerodynamics to improve range. To extend the driving distance, electric vehicles are designed with streamlined bodies and aerodynamic features like air dams and spoilers. These design elements reduce drag, increase efficiency, and contribute to better range and performance.3.4Software and Smart Features

One of the standout features of electric vehicles is their integration of software and advanced technologies. Many EVs come equipped with advanced driver-assistance systems (ADAS), including autonomous driving capabilities, automatic parking, and smart voice assistants. Furthermore, the battery management system (BMS) is vital in optimizing the battery’s performance and lifespan. The focus on software and smart technology is a key part of the EV design, distinguishing it from traditional cars.4. Profound Industry Impact

4.1Development of Emerging Technologies

The rise of electric vehicles has driven advancements in various emerging technologies, particularly in battery technology, charging infrastructure, and autonomous driving systems. As battery energy density continues to improve, the driving range and charging speed of EVs will progressively match or even exceed that of traditional cars.4.2Changes in Talent Requirements

The shift toward electric vehicle production has changed the types of skills required in the automotive industry. While traditional car manufacturers still require mechanical engineers, the demand for software developers, battery researchers, and electrical engineers has grown significantly.4.3Environmental Impact and Regulations

Electric vehicles contribute to reducing greenhouse gas emissions and are aligned with global carbon-neutral goals. Governments worldwide have introduced policies supporting EV adoption, such as purchase subsidies, tax exemptions, and stricter emissions regulations for traditional internal combustion engine vehicles.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh