What is the tensile strength of iron?

2024-12-26 16:09:19 hits:0

Cast iron, as a widely used metallic material in the industrial sector, features mechanical properties that are crucial for evaluating its performance. Among these properties, tensile strength is a key parameter that measures a cast iron's ability to withstand maximum stress under tensile conditions. This article delves into the definition of tensile strength in cast iron, its influencing factors, and provides relevant data. Additionally, it introduces Iron Valley Company's services for customized processing and manufacturing of cast iron parts.

I. Definition of Tensile Strength

Tensile strength, also known as ultimate tensile stress or tensile breaking strength, refers to the maximum stress a material can endure during tensile testing. It is expressed in terms of force per unit area, such as megapascals (MPa). This property signifies the maximum load-bearing capacity of a material under static tensile conditions and marks the transition from uniform plastic deformation to localized plastic deformation. As stress increases during tensile testing, the bonding between atoms and molecules within the material gradually weakens until a critical point is reached, causing the material to fracture. The stress corresponding to this critical point is defined as tensile strength.

II. Influencing Factors

Tensile strength in cast iron is influenced by several factors, including but not limited to:

- Composition: The tensile strength of cast iron is closely related to its chemical composition. For instance, gray cast iron, ductile (nodular) cast iron, and white cast iron exhibit different tensile strength standards due to variations in composition and manufacturing processes.

- Microstructure: Ferrite has the lowest tensile strength, while martensite exhibits higher tensile strength.

- Nodularity: For ductile cast iron, a higher nodularity typically results in higher tensile strength. When nodularity exceeds 80%, the loss of tensile strength and elongation is minimal.

- Carbides: The number, distribution, and morphology of carbides significantly impact the tensile strength of cast iron. An increase in carbide content may lead to a decrease in tensile strength.

- Wall Thickness: The wall thickness of cast iron parts also affects its tensile strength. Generally, thicker cast iron parts may possess higher tensile strength.

- Heat Treatment: Various heat treatment processes, such as austempering, can significantly enhance the tensile strength and other mechanical properties of cast iron.

III. Tensile Strength Data

Different types of cast iron have varying tensile strength standards. Here are some common tensile strength data for cast iron:

- Gray Cast Iron: Gray cast iron typically has a tensile strength requirement greater than 150 MPa (GB standard) or 200 MPa (ISO standard). These standards ensure sufficient load-bearing capacity during application.

- Ductile (Nodular) Cast Iron: Ductile cast iron has relatively higher tensile strength requirements, usually exceeding 370 MPa (GB standard) or 500 MPa (ISO standard). This makes ductile cast iron suitable for applications requiring complex stress environments.

- White Cast Iron: White cast iron also demands high tensile strength, typically greater than 270 MPa (GB standard) or 370 MPa (ISO standard). This type of cast iron is characterized by high strength and hardness, making it ideal for manufacturing mechanical components that require high hardness and wear resistance.

Please note that these tensile strength data serve as references only. Actual values may vary due to specific material composition, manufacturing processes, and heat treatment conditions. Therefore, when selecting cast iron materials, comprehensive evaluation and selection based on actual application environments and requirements are necessary.

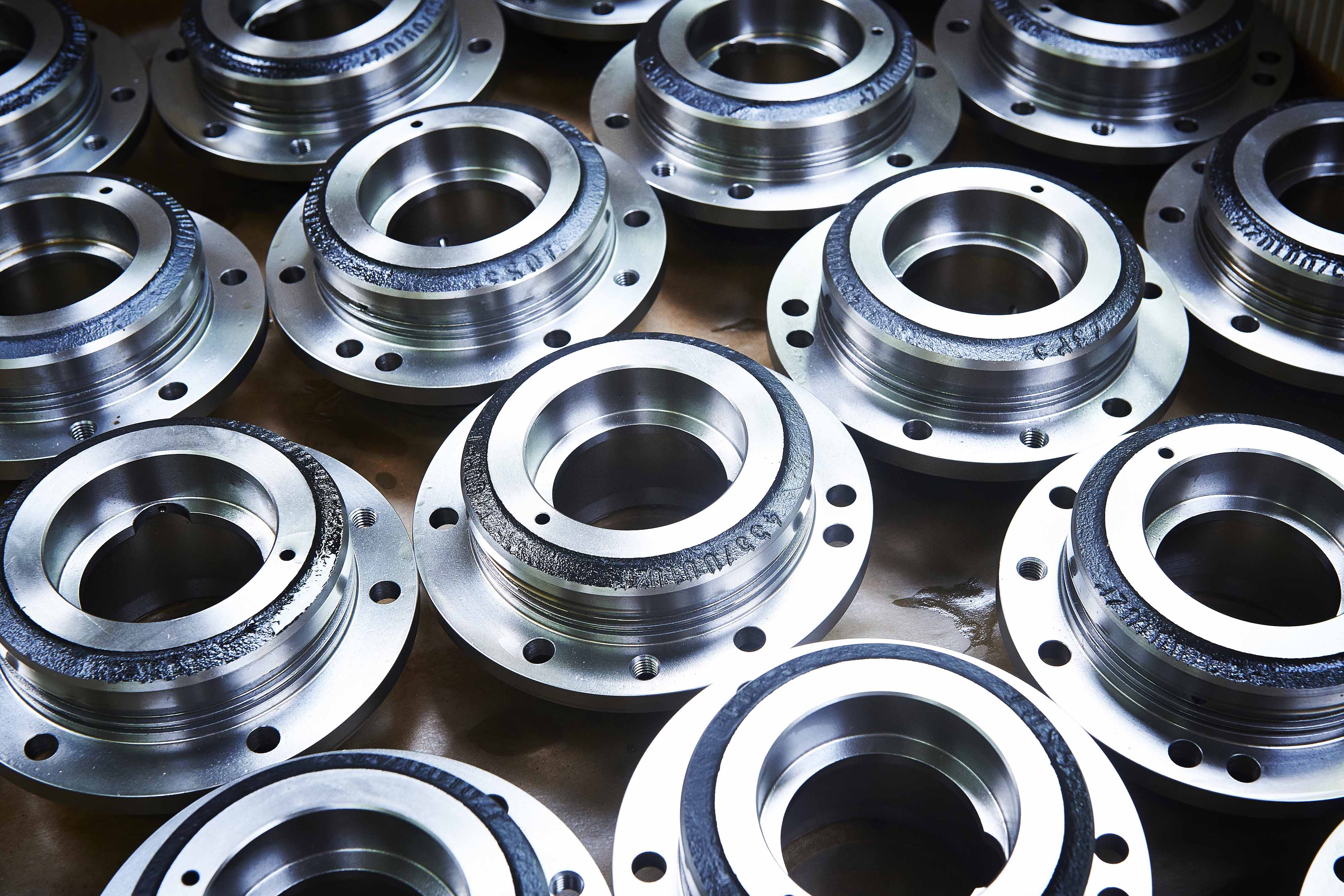

Tiegu specializes in customized processing and manufacturing of cast iron parts, boasting extensive production experience and advanced technological equipment. We accept customized orders for various cast iron parts, including but not limited to gray cast iron, ductile cast iron, and white cast iron. Our products are widely used in fields such as pipelines, automobiles, engineering machinery, agricultural machinery, etc., and are highly trusted and praised by customers.

If you have customized processing needs for cast iron parts, please contact tiegu. We will provide you with high-quality products and services to meet your diverse requirements. We look forward to your cooperation!

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh