Green Design and Manufacturing of Customized Castings

2024-12-25 14:48:05 hits:0

In the manufacturing industry, the casting sector holds a pivotal position, and as a company specializing in customized castings, Tiegu understand the importance of pursuing both production efficiency and green, sustainable practices. The green design and manufacturing of customized castings are not only crucial for our long-term development but also reflect our commitment to social responsibility. This article delves into the strategies for green design and manufacturing of customized castings, presenting specific data and cases to illustrate their application and effectiveness in practice.

I. The Core Concept of Green Design

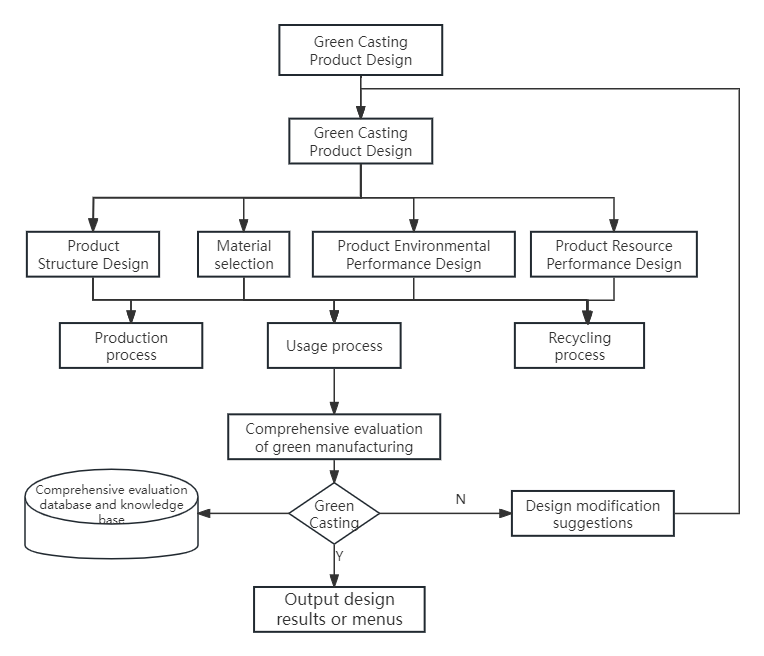

Green design, also known as ecological design or environmental design, is an approach aimed at reducing negative environmental impacts. In the casting industry, green design for customized castings means meeting specific customer needs while minimizing environmental impacts through optimized design, selection of eco-friendly materials, reduced energy consumption, and waste generation.

- Data Support: According to statistics, in traditional casting processes, the utilization rate of raw materials is often below 50%, with a significant amount of raw materials converted into waste emissions. Through green design, Tiegu can increase raw material utilization to over 70%, significantly reducing resource waste.

II. Green Design Practices for Customized Castings

- Optimized Product Design:In the design stage of customized castings, we focus on the rationality of product structure and lightweight design, reducing the generation of excess and scrap materials through precise calculations and optimized layouts. For example, in the customized design of automotive engine components, we adopt cavity optimization technology, reducing material usage by about 20% while ensuring product performance.

- Case Share: An automotive manufacturer entrusted us with customizing an engine block. Through green design, we successfully reduced the block's weight by 15% and increased material utilization to 75%, significantly lowering production costs and energy consumption.

- Selection of Eco-Friendly Materials: In material selection, we prioritize recyclable eco-friendly materials, such as recycled metals and biobased materials. These materials not only reduce dependence on raw resources but also lower greenhouse gas emissions during production.

- Data Comparison: Using recycled metals for casting customized castings can reduce greenhouse gas emissions by about 30% compared to traditional casting materials.

- Energy-Saving and Emission-Reduction Technologies: In the manufacturing process, we employ energy-efficient melting equipment and control systems, as well as environmentally friendly coatings and additives, further reducing energy consumption and environmental pollution.

- Actual Results: By introducing energy-efficient melting equipment, we reduced energy consumption by 20%. Additionally, the use of environmentally friendly coatings reduced harmful gas emissions by about 50%.

III. Case Studies of Green Manufacturing

Case One:

A large gearbox casting customized for an engineering machinery manufacturer. Tiegu adopted green manufacturing techniques, precisely controlling melting temperature and time to reduce energy consumption and waste generation. Simultaneously, we utilized a waste heat recovery system to preheat raw materials with the heat generated during melting, further improving energy utilization efficiency.

Data Presentation: The project's energy utilization rate increased by 30%, waste was reduced by 40%, and the customized gearbox casting exhibited stable quality and excellent performance, earning high praise from the customer.

Case Two:

A wind turbine base customized for a wind energy equipment manufacturer. During design and manufacturing, we fully considered the product's disassemblability and recyclability, adopting a modular design for easy subsequent maintenance and recycling. Additionally, we utilized advanced casting simulation software to precisely simulate and optimize the casting process, ensuring a one-time pass rate for the product.

Outcome Presentation: The customized casting for this project can achieve over 90% material recovery utilization at the end of its lifecycle, significantly reducing environmental pollution. Meanwhile, through precise simulation and optimization, we reduced production costs by about 15%.

IV. Looking Ahead

The green design and manufacturing of customized castings are effective pathways to achieving sustainable development in the casting industry. By continuously optimizing product design, selecting eco-friendly materials, and adopting energy-saving and emission-reduction technologies, Tiegu can not only meet specific customer needs but also bring dual economic and social benefits to the enterprise.

In the future, Tiegu will continue to increase investment in research and development of green technologies, optimize production processes, improve resource utilization efficiency, and strive to integrate green design and manufacturing concepts throughout the entire lifecycle of customized castings.

Simultaneously, Tiegu look forward to collaborating with more partners to jointly promote the green transformation and sustainable development of the casting industry, contributing to the realization of a vision of harmonious coexistence between humanity and nature.

In summary, the green design and manufacturing of customized castings are effective ways to achieve sustainable development in the casting industry. By continuously optimizing product design, selecting eco-friendly materials, and employing energy-saving technologies, Tiegu can not only fulfill specific customer requirements but also enhance the enterprise's core competitiveness, bringing both economic and social benefits.

If you are interested in our company's products, please contact us and we will provide you with attentive service.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh