How to perform sandblasting treatment on cast iron?

2024-12-24 17:33:41 hits:0

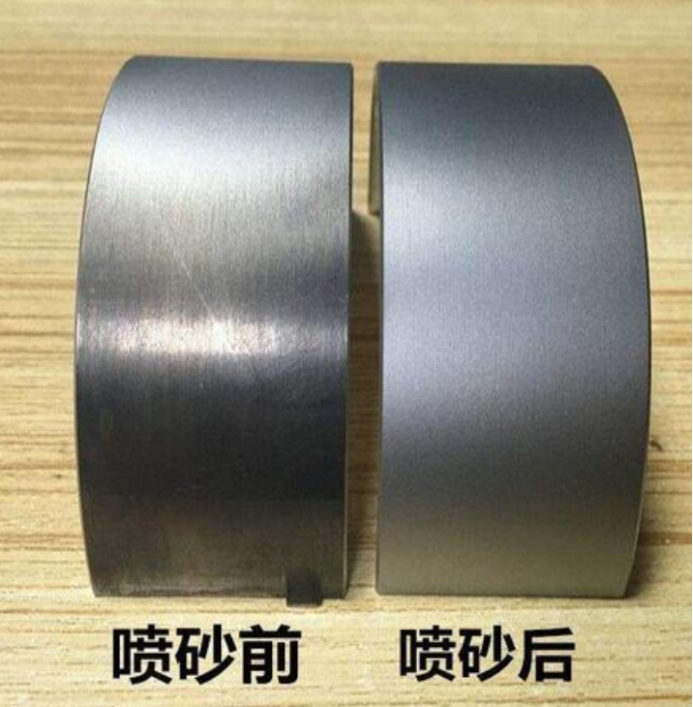

Shot blasting, or sandblasting, is a commonly used surface treatment method for cast iron to effectively remove oxides, sand particles, and other impurities on the surface, thereby improving the surface quality and adhesion of the cast iron. Here's a detailed guide on how to perform shot blasting treatment on cast iron:

1. Preparation Before Shot Blasting

- Select Suitable Shot Blasting Media: Choose appropriate blasting media based on the material and surface requirements of the cast iron, such as steel shot, glass beads, aluminum oxide, etc. Different media have different cutting abilities and finishing effects.

- Prepare Shot Blasting Equipment: Use efficient shot blasting equipment and ensure that its nozzles, compressed air, and media supply systems are functioning properly. Regularly maintain and inspect the equipment to maintain its optimal performance.

2. Shot Blasting Process

- Adjust Shot Blasting Parameters: Set the shot blasting pressure, spray angle, and distance to obtain the best surface treatment effect. Generally, the shot blasting pressure should be between 0.4~0.8 MPa, which can be adjusted according to the material and requirements of the cast iron.

- Perform Shot Blasting: Use compressed air to form a high-speed jet and spray the blasting media (such as copper ore sand, quartz sand, iron sand, sea sand, and emery) onto the surface of the cast iron to be treated. The impact and cutting action of the abrasive on the surface of the cast iron will make the surface clean and achieve different roughness.

3. Post-Shot Blasting Treatment

- Clean Up: After shot blasting, clean up the waste material in the shot blasting chamber to keep the working environment tidy.

- Inspect and Evaluate: Inspect the surface of the cast iron to ensure that the oxides, sand particles, and other impurities have been completely removed, and evaluate the roughness and cleanliness of the surface.

- Additional Surface Treatment: If necessary, additional surface treatment processes such as painting or electroplating can be performed to further enhance the performance and appearance of the cast iron.

4. Safety Precautions

- Wear Protective Equipment: During the shot blasting process, a large amount of dust and noise will be generated. It is essential to wear appropriate personal protective equipment, such as dust masks, protective glasses, and earplugs, to ensure the safety of the operators.

- Ventilation and Dust Removal: Ensure adequate ventilation and dust removal measures are in place to reduce the exposure of operators to dust and harmful substances.

5. Quality Control

- Regular Inspection and Maintenance: Regularly inspect and maintain the shot blasting equipment to ensure its stable and reliable operation.

- Control Blasting Media Quality: Ensure the quality of the blasting media to avoid introducing impurities or damaging the surface of the cast iron.

In summary, shot blasting treatment for cast iron involves preparations, adjusting process parameters, performing the blasting operation, post-treatment, safety precautions, and quality control. By following these steps, the surface quality and performance of the cast iron can be significantly improved.

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh