Forklift Parts

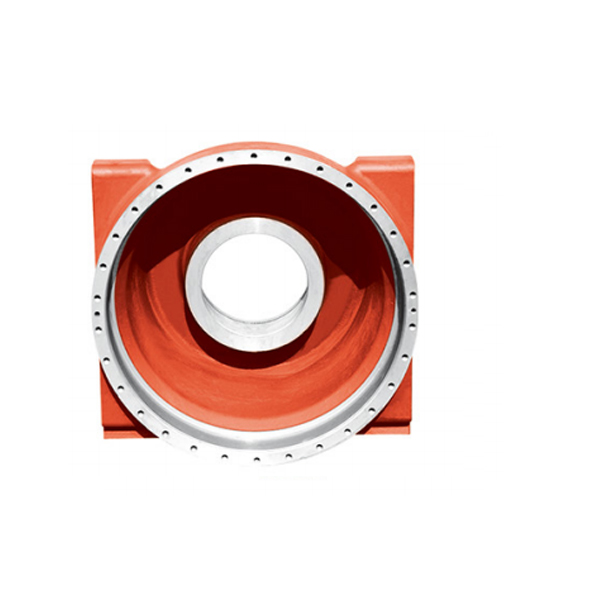

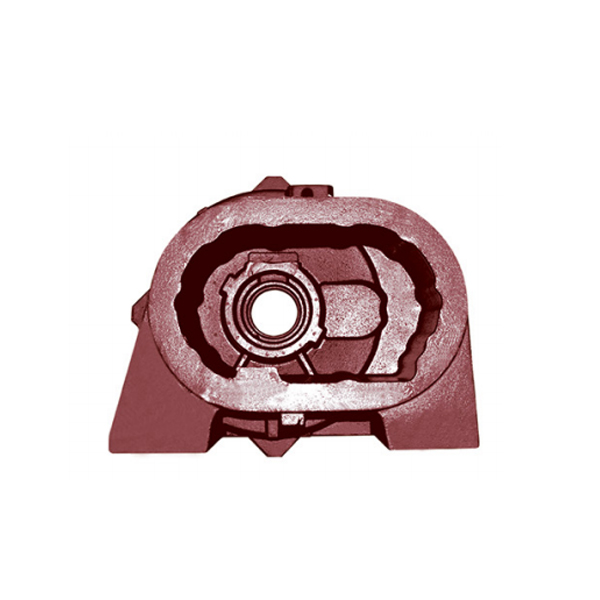

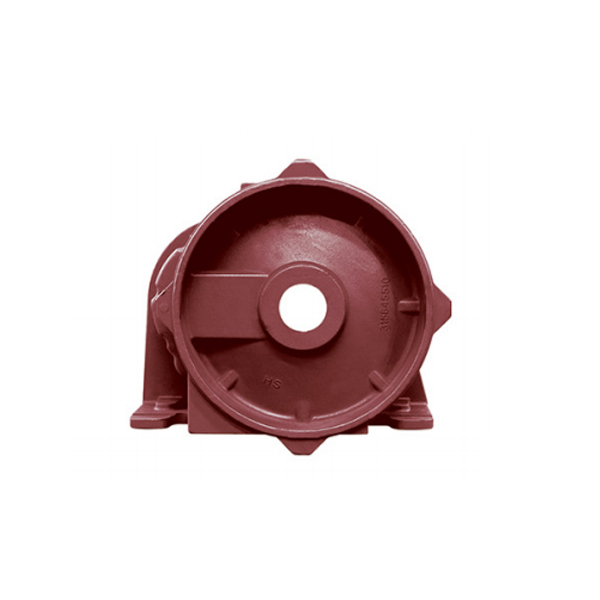

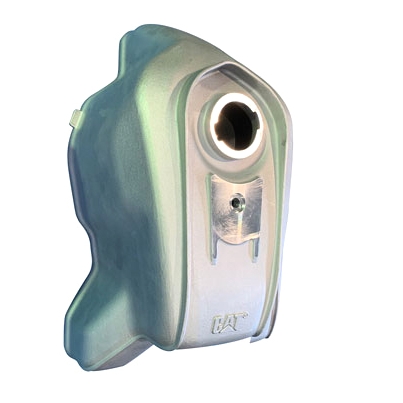

In the stable operation and efficient work of forklifts, every single part plays a crucial role. Tiegu is committed to providing you with a full range of high-quality forklift parts, such as front axle housings, rear axle housings, front wheel hubs, rear wheel hubs, and steering knuckles,etc.

Introduction

One-Stop Supply of High-Quality Forklift Parts

I. Introduction

II. Display of Core Parts

III. Brand Coverage and Advantages

FAQ

Q1:How do you ensure your product quality?

Q2:What are your main casting products?

Q3:What are the grades of castings you produce?

Q4:Do you have surface treatment capabilities?

Q5:What casting production processes do you have?

Q6:What are your advantages?

Q7:What after-sales services do you provide?

Q8:Do you have the capability for customized processing?

Q9:How can I establish a partnership with you?

A: You can fill out an online form and leave your information, or directly contact our team.

Customizable

Transportation modes:Including sea transportation, railway transportation, and road transportation.

Minimum order quantity:Comprehensive evaluation based on actual orders.

Qualification certification: Complete qualifications to ensure reliable quality.

Sales countries:We have provided products to users regions including Asia, Southeast Asia, Europe, North America, and Africa, serving countries such as the United States, Japan, South Korea, France, Germany, Thailand, Vietnam, the United Arab Emirates, and Saudi Arabia. Looking ahead, we eagerly anticipate cooperating with more global buyers.

Photos

-

Reducer Housing Manufacturer | Custom Cast Iron & Steel Gear Reducer Casings

-

Industrial Gearbox Manufacturer | Custom Cast Iron/Steel Gearboxes for Mining & Wind Energy

-

High-Performance Gearbox End Caps | Industrial-Grade Sealing Solutions for Gearboxes

-

Electric Motor Castings Manufacturer | Custom Aluminum & Iron Motor Housings

-

High-Quality Taper Bushed Pulleys | SPB/SPA Series | Customizable & Durable

-

Gantry Castings Manufacturer | Custom Steel & Iron Gantry Frame Castings

-

Large Castings Manufacturer | Heavy Iron & Steel Casting Parts Supplier

-

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh