You can easily connect with quality foundries in China for lower prices and more choices!

A strategic supply chain partner

12 Strategically Partnered ISO/TS16949-Certified Foundries ,and 200 reserve suppliers.

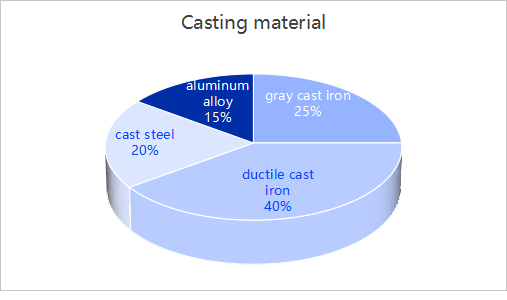

Casting material: gray cast iron / ductile cast iron / cast steel / aluminum alloy.

Casting processes such as sand casting, precision casting,sodium silicate casting, Die Casting, Silica sol casting,investment casting and CNC Machining.

The annual sales volume of castings exceeds 1.2 million tons, and the maximum production capacity of a single factory reaches 300,000 tons.

Tiegu for you to process all kinds of customized castings

Automotive and Transportation

Products:Precision castings for automotive parts, rail transit, marine and offshore engineering, etc.

Achievement:We are a supplier to 10 first - tier suppliers of major vehicle manufacturers.

Mechanical Manufacturing

Products:Valves, pump bodies, agricultural machinery, construction machinery

Achievement:We serve the world's top 5 construction machinery manufacturers.

General Industrial Products

Products:Enameled cast iron pots, ductile iron pipes, manhole covers, etc.

Energy and Environmental Protection

Products:Hydropower and wind power equipment, environmental protection equipment.

Exhibition of Some Deep - Partnered Foundries

Foundry name::SHSCC Co., Ltd

Foundry name::SHSCC Co., Ltd

Founded in 2002, registered capital 92 million yuan

Introduction of foundry:

The company has more than 1,000 employees and more than 100 professional technicians. The company has a 230M'smelting blast furnace with 6000KW blast furnace gas waste heat generator set, five large casting workshops, three machining workshops, a 35KV self-provided power station, covering a total area of 200,000 square meters. With the constant selection of raw materials, scientific and accurate proportioning, and excellent craftsmanship, the company has an annual output of more than 300,000 tons of high-quality pig iron for casting, ductile cast iron, and high-purity pig iron. We have mature casting technology such as disappearing mold, film- covered sand, resin sand, clay sand, iron type sand-covered and so on. Precision casting capacity of 52,000 tons, 92,000 tons of short-flow process, the products involved in the military, robotics, large wind power, marine, rail transit, automotive and large engineering vehicle parts, CNC intelligent machine tools, elevators, motor parts, industrial doors, municipal facilities and so on. The company's annual sales revenue is nearly 2 billion yuan.

Foundry name: WHFT Co., Ltd

Foundry name: WHFT Co., Ltd

Company introduction:

The foundry is located in Wuhu City, Anhui Province, covering an area of about 65 acres.

The company was founded on March 15, 2017, with a registered capital of 40 million yuan, on-the-job More than 180 employees, with more than 10 invention patents, modern high-tech enterprises.

The company has a production capacity of 6 tons / and 4 tons / two sets of medium frequency electric furnace, resin sand making

We have 4 resin sand molding production lines, 1 clay sand production line, and 4 multi-contact production lines.

The company has first-class technology and management team, complete physical and chemical testing equipment.

The main products are valves, pumps and other fluid castings for water supply industry. Annual design Annual production capacity of 100,000 pieces (30,000 tons of castings) special water supply industry fluid products.

Foundry name: BLC Co., Ltd

Company introduction:

Founded in 1959, the company has more than 60 years of crankshaft production history, the main business scope is crankshaft and engine parts, all kinds of castings, sales and import and export business.

The main business scope is crankshafts and engine parts, all kinds of castings sales and import and export business.

The company covers an area of 416,000 square meters (more than 600 acres), with a building area of 115,000 square meters and 460 employees, including 86 professional technicians.

The company has an annual production capacity of 20,000 tons of various types of high-performance ductile iron castings, and an annual production capacity of more than 500,000 crankshafts of various types of ductile iron and forged steel. International market: supporting construction machinery and automobile engines of Kohler (USA), Carter (USA), Fiat (Italy), Hawksley Mann (UK), FIAT (Pakistan), BS (South Korea) and so on.

Foundry name: SSFM Co., Ltd

Company Introduction: founded in 2001, has been deeply cultivating in the field of livelihood products for twenty years, the company has a kitchenware design company, mold design company, trade and sales company, rough casting factory, enamel production factory, it is a professional manufacturing enterprise integrating independent research and development, design, production, testing and sales of kitchenware. The company has a complete range of products, more than 100 varieties of enameled and vegetable oil cast iron kitchenware are exported to North America, Western Europe, Australia, Hong Kong and Taiwan and other countries and regions, and are highly praised by foreign businessmen and domestic users. Over the years, the foundry focuses on product research and development and innovative design, the introduction of advanced equipment, the refinement of the core technology, the company uses DISA automatic vertical parting boxless injection molding machine, DISA full detection sand mixer, automatic pouring machine and a number of other domestic advanced production equipment, produced a number of beautiful and practical, high quality kitchenware to withstand the test of time.

FAQ

1、How do you guarantee the quality of your products?

A: We strictly follow international standards and industry norms for production and quality control. All products undergo strict quality testing to ensure that they meet customers' requirements and expectations. Meanwhile, we also provide perfect quality assurance system and after-sales service, integrity management, service first.

2、What are your main casting products?

Tiegu's castings are widely used in automotive, construction machinery, mining machinery, agricultural machinery, machine tools, pipelines, new energy, municipal and other fields, specific parts such as heavy truck chassis parts: one-piece cross member, jockey bolt seat, leaf spring seat, support seat, balance shaft shell, steering gear housing, engine bracket; engine parts: flywheel, flywheel shell; axle parts: base plate, hoofs, wheel hubs, brake hubs, calipers, brackets, Differential housing and wheel edge; wind power parts: motor seat and lower body; agricultural machinery parts: counterweight block, etc.

3、What grades of castings do you produce?

The castings provided by Tiegu are mainly gray cast iron and ductile iron: gray iron grades: HT100, HT150, HT200, HT250, HT280, HT300, HT350, HT400; ductile iron grades: QT400, QT450, QT500, QT600, QT700, QT800 and so on.

4、Do you have surface treatment capability?

Professional painting line and paint spraying room can meet all kinds of primer and top coating requirements.

5、What kind of casting production process do you have?

Currently, Tiegu has sand casting, molten film casting (also known as wax casting), metal casting, pressure casting, centrifugal casting, solid casting (also known as evaporative film casting), and V process (also known as vacuum casting).

6、What are your advantages?

1, Tiegu has its own pig iron and ferroalloy supply chain channels, there are material cost advantages and material security advantages.

2、Tiegu self-developed product line and integrate thousands of domestic high-quality casting supplier resources, good reputation for cooperation.

3、Can meet the casting needs of 99% of users.

7、What after-sales service do you provide?

A: Tiegu provides you with after-sales service including product consultation, technical support, maintenance and replacement. If you encounter any problems or need help in the process of use, please feel free to contact our customer service team. We will be happy to provide you with quality service and support.

8、Do you have the ability to process customized products?

A: We have a machining workshop, supporting a variety of small, medium and large CNC gantry machine tools and machining centers and other professional equipment, as well as many years of casting engineers, can provide a full range of customized services!

9、 How can I establish a cooperative relationship with you?

A: You can fill in the online form (add hyperlinks), leave your information, or directly contact the Tiegu team.

E-mail address: zbw@tiegu.net

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh