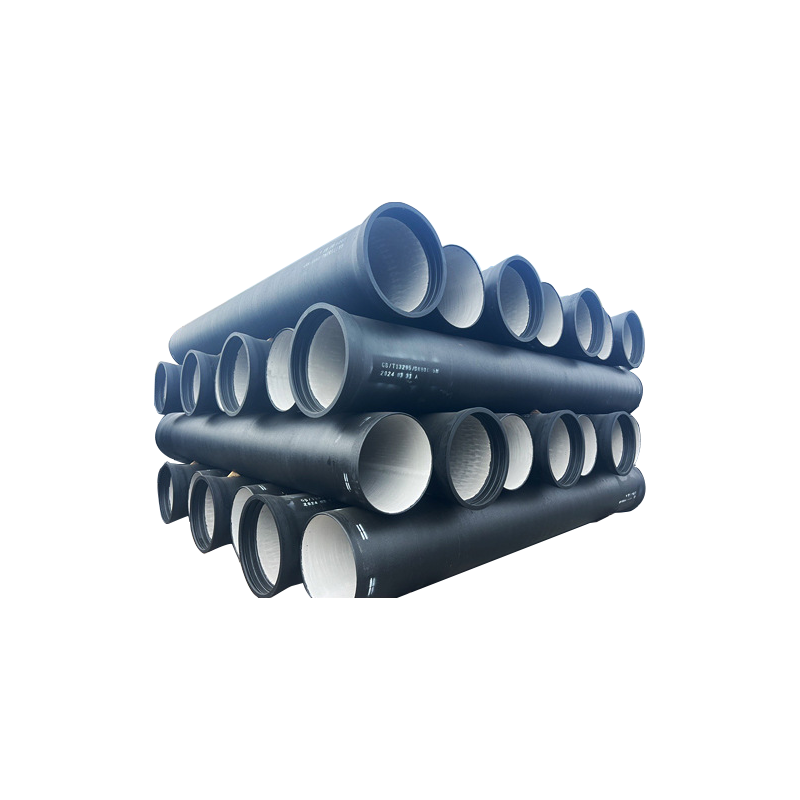

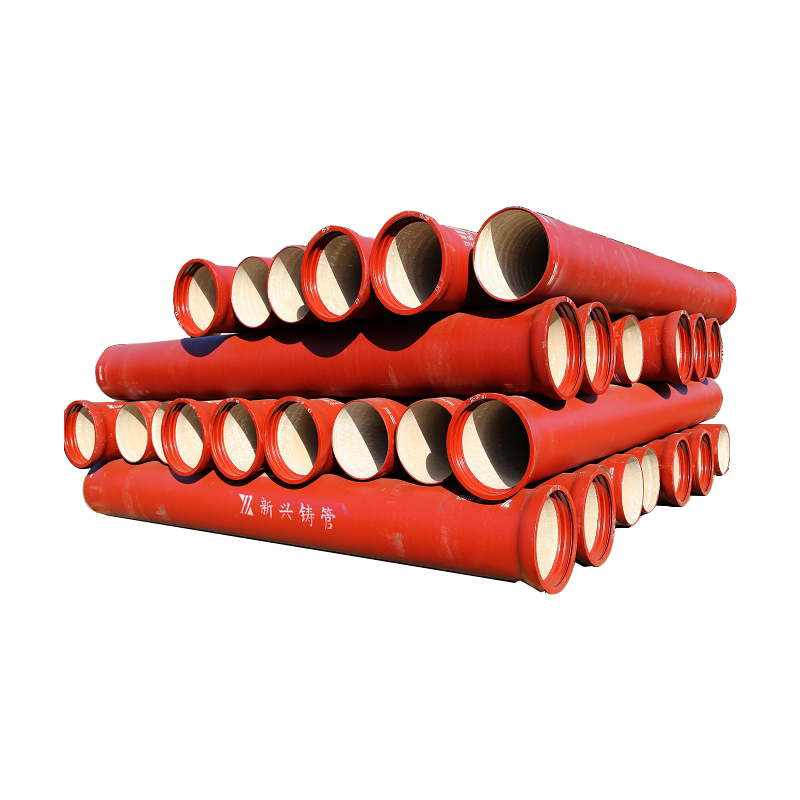

Ductile Iron Pipe

DN80-DN3000.The product categories of ductile iron pipes are: water supply pipes, drainage pipes, and heat pipes. The varieties include polyurethane lining pipes, epoxy resin lining pipes, epoxy ceramic lining pipes, PE lining pipes, zinc aluminum alloy pipes, top pipes, drag pipes, self anchored pipes, sewage pipes, etc.You are welcome to consult at any time.

Introduction

Customizable

Transportation modes:Including sea transportation, railway transportation, and road transportation.

Minimum order quantity:Comprehensive evaluation based on actual orders.

Qualification certification: Complete qualifications to ensure reliable quality.

Sales countries:We have provided products to users regions including Asia, Southeast Asia, Europe, North America, and Africa, serving countries such as the United States, Japan, South Korea, France, Germany, Thailand, Vietnam, the United Arab Emirates, and Saudi Arabia. Looking ahead, we eagerly anticipate cooperating with more global buyers.

Definition and Overview of Ductile Iron

Ductile iron pipes, also known as nodular iron pipes, nodular cast iron pipes, or more commonly, centrifugal ductile iron pipes, are produced by adding nodulizing agents to molten cast iron and then casting it at high speed through a centrifugal ductile iron casting machine. They are abbreviated as DIP (Ductile Iron Pipe). With their superior performance, strong adaptability, and diverse product categories, centrifugal ductile iron pipes are widely used in various fields and have broad development prospects.

Ductile iron, a type of cast iron, is an alloy of iron, carbon, and silicon. In ductile iron, graphite exists in spherical form, generally ranging in size from grade 6 to 7. Quality standards require the nodularization grade of cast pipes to be controlled at grades 1 to 3 (nodularity ≥ 80%), which significantly improves the material's mechanical properties, giving it the essence of iron and the performance of steel. After annealing, the microstructure of centrifugal ductile iron pipes consists of ferrite with a small amount of pearlite. The proportion of pearlite in small-diameter pipes is generally not more than 20%, while that in large-diameter pipes is generally controlled at around 25%, further optimizing the mechanical properties, strength, toughness, and exhibiting excellent pressure resistance and ductility.

Tieguexport - Ductile Iron Pipe Manufacturer and Supplier

The product has various interface forms such as T-type, GT type, self anchored type, etc. The inner lining of the pipe is made of cement mortar, polyurethane, PE, epoxy ceramics, etc. to meet different water quality transportation requirements. Spray zinc, zinc aluminum alloy, polyurethane, PE and other external anti-corrosion treatment technologies are suitable for different corrosive soil environmental conditions and are ideal pipes for urban water supply and heating.

The production of Tiegu cast iron pipes can meet national or European standards such as GB13295/GB26081/EN598/EN545/GB17456/GB17457, and can also produce ductile iron pipes according to Australian and Brazilian standards, and can be customized according to user needs.

As ductile iron pipe suppliers, we will provide you with high-quality pipes and after-sales service.

Classification of ductile iron pipe products

The product categories of ductile iron pipes are: water supply pipes, drainage pipes, and heat pipes. The varieties include polyurethane lining pipes, epoxy resin lining pipes, epoxy ceramic lining pipes, PE lining pipes, zinc aluminum alloy pipes, top pipes, drag pipes, self anchored pipes, sewage pipes, etc.

Performance characteristics of ductile iron pipes:

High strength and toughness:

Centrifugal ductile iron pipe have excellent mechanical properties, with a tensile strength generally ranging from 420 to 550 MPa and an elongation rate of over 7%. They can withstand high internal and external pressures and impacts.

Corrosion resistance:

Ductile iron pipes undergo internal and external anti-corrosion treatment, such as spraying epoxy resin, asphalt paint or coating cement mortar, which can effectively resist the corrosion of soil, water quality and chemical media, and extend the service life of the pipeline.

Good sealing performance:

Ductile cast iron pipes are usually connected by socket or mechanical connections to ensure the sealing of the pipeline system and effectively prevent leakage problems.

Easy installation:

Ductile iron pipe have a large elongation and flexible interface, making the installation process easier and faster, and reducing construction costs.

Model and size

1、 Main specifications and models

The main specifications and models of Tieguexport cast pipes range from DN80 to DN3000 millimeters, covering various sizes from small to large diameters. This specification range enables Tieguexport Cast Pipe to be widely used in various fields such as water supply, drainage, gas transportation, industrial transportation, and agricultural irrigation.

2、 Specific size range

Small caliber pipes: DN80, DN100, DN150, DN200, etc. These sizes of pipes are usually used in small water supply systems, household water use, and other scenarios.

Medium caliber pipes: DN300, DN400, DN500, DN600, DN800, DN900, DN1000, etc. These sizes of pipes are suitable for medium-sized water supply systems, drainage systems, and some industrial transportation scenarios.

Large caliber pipes: DN1200 and above, including DN1200, DN1400, DN1600, DN1800, DN2000, DN2200, DN2400, DN2600, etc. These large-sized pipes are usually used in large-scale water supply systems, drainage systems, gas transmission systems, and water conservancy projects.

Special size customization

In addition to the standard specifications and models mentioned above, Tieguexport Cast Pipe can also be customized for production according to customers' special needs. Whether it is pipes of special sizes or pipes with special properties, Tieguexport Cast Pipe can provide products that meet customer needs.

Application fields of ductile iron pipes

Ductile iron pipes, also known as ductile iron pipes, are widely used in various fields due to their excellent characteristics such as high strength, corrosion resistance, pressure resistance, good sealing, easy assembly, and long service life. The following is a detailed summary of its main application areas:

1. Water supply system

Tap water pipeline:

Ductile iron pipes have become the main pipe material in urban water supply systems due to their excellent corrosion resistance and pressure resistance, which can withstand the impact of high-pressure water flow, ensuring the safety and hygiene of water quality.

Agricultural irrigation:

In agricultural irrigation systems, ductile iron pipes are used to transport large areas of irrigation water, and their durability and economy are highly favored by agricultural irrigation engineering.

2. Drainage system

Urban drainage:

Ductile iron pipes are one of the main materials for drainage pipelines, which can withstand the impact of high-pressure water flow and the erosion of corrosive substances. They are widely used in urban drainage systems, including rainwater and sewage discharge.

Road and bridge drainage:

In road and bridge construction, ductile iron pipes are commonly used for bridge drainage pipes, tunnel drainage pipes, etc., to ensure smooth drainage of roads and bridges and reduce the damage of accumulated water to roads and bridges.

3. Gas system

Gas pipeline: Ductile iron pipes are also widely used in gas pipeline systems, with good sealing and strong seismic resistance, which can effectively prevent natural gas leakage and ensure the safety and reliability of gas transmission.

4. Industrial sector

Industrial pipelines:

In industries such as chemical, petroleum, natural gas, metallurgy, and pharmaceuticals, ductile iron pipes can meet the needs of various complex working conditions. Their corrosion resistance and high pressure resistance ensure the stable operation of the production process.

Transporting oil, gas, and chemicals:

Ductile iron pipes are commonly used to transport these media, and their high temperature resistance and corrosion resistance ensure the orderly operation of normal work.

5. Other fields

Heating system:

Ductile iron pipes are also suitable for pipeline construction in heating systems, and their excellent corrosion resistance and pressure resistance can ensure the stable operation of the heating system.

Water conservancy engineering:

In water conservancy engineering, ductile iron pipes also play an important role, such as used in irrigation, drainage and other systems.

Tieguexport cast iron pipes have important application value in multiple fields such as water supply, drainage, gas transportation, industrial transportation, and agricultural irrigation due to their excellent performance and wide range of applications.

Precautions for choosing ductile iron pipes

When choosing the model and size of Tieguexport cast pipes, customers need to consider specific application scenarios and requirements. For example, in the water supply system, factors such as water pressure, water flow rate, and pipeline material need to be considered; In the drainage system, factors such as drainage volume, pipeline slope, and drainage efficiency need to be considered. In addition, attention should be paid to factors such as the connection method, installation method, and maintenance method of pipelines to ensure the normal operation and long-term use of the pipeline system.

In summary, Tieguexport Cast Pipe has a wide range of models and sizes, which can meet the needs of different fields and scenarios. Customers need to consider specific application scenarios and needs when making choices to ensure they select the most suitable product for themselves.

The advantages of tieguexport

1) Product advantages and cost advantages

Independent research and innovation capability:

We have a professional R&D team and advanced production equipment, capable of independently developing and producing high-quality products that meet international market demands. We continuously invest resources in product development and improvement to maintain the innovation and competitiveness of our products.

2) Rich and stable supply chain with diverse product lines:

In addition to independently developed products, it can also integrate the resources of high-quality domestic suppliers and provide diversified product choices. After years of research, we have selected hundreds of reputable and high-quality suppliers in China to establish long-term cooperative relationships. Being able to meet the needs of different customers and markets, and enhance market competitiveness.

3) Professional Service Team

We have a senior foreign trade manager, professional follow-up, customs clearance, and finance team, providing one-stop services.

Service guarantee: Emphasize after-sales service, establish a sound system, and respond quickly to customer needs.

Good reputation: integrity-based, winning the trust of numerous customers, and establishing a good corporate image.

We have a professional international trade team that can handle various international trade affairs to ensure smooth transactions.

Our team members are all professionals in the steel and casting industries, with a team of senior technical personnel ready to provide technical consulting services to customers at any time, and can help you solve the vast majority of production technology problems.

4) Quick delivery:

Under normal circumstances, we can deliver within 10 working days after the factory receives the advance payment.

Development trend of ductile iron pipes

With the acceleration of global urbanization and the continuous promotion of infrastructure construction, the demand for ductile iron pipes will continue to grow.

The continuous emergence of new anti-corrosion technologies and connection methods will further improve the performance and service life of ductile iron pipes, and broaden their application fields.

The deep-rooted concept of environmental protection and sustainable development will promote the development of the ductile iron pipe industry towards a greener and low-carbon direction.

Contact Us

If you are interested in our products or have any questions, please feel free to contact us at any time.

Phone+86 152 5613 5588

Email: zbw@tiegu.net

Photos

en

en  fra

fra  de

de  ru

ru  gle

gle  th

th  ara

ara  it

it  jp

jp  kor

kor  zh

zh